Ballistic protection panels manufacturer relies on automation for high throughput, efficiency

Maine-based CW Top Shops honoree Compotech Inc. recently doubled its manufacturing space and team to produce modular composite panels for defense applications via light resin transfer molding (LRTM).

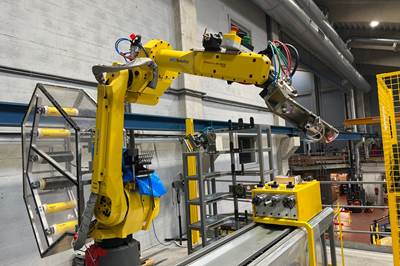

Compotech Inc. invested in six six-axis robotic arms that automate a variety of manual tasks such as sanding, welding and packaging in the production of modular, ballistic protection panels. Photo Credit, all images: Compotech Inc.

(Brewer, Maine, U.S.) was founded in 2011 with the goal of leveraging the team’s composites and defense knowledge “to create a lasting manufacturing company in Maine,” says Paul Melrose, president of Compotech.

The company specializes in modular, ballistic protection panels made from composite materials, such as its , 4 × 7-foot tall panels used for deployment on military bases; and its latest product, a redeployable hard shelter system that is easily assembled in under 30 minutes.

To manufacture these products, the company and its 47-employee team operate a 130,000-square foot facility with 44,000 square feet dedicated to manufacturing space.

Compotech is one of the honorees for CW Top Shops 2023, an annual benchmarking survey program run by ÂÌñÏ×ÆÞ and Gardner Intelligence (Cincinnati, Ohio, U.S.). Composites fabricators participate by filling out a survey (the is open through April 30, 2024) detailing the company’s operations over the past year. Each participating company is then sent a customized report from Gardner Intelligence, illustrating the facility’s performance on a variety of metrics in comparison with others who have taken the survey. The highest-performing facilities across metrics qualify for distinction as a CW Top Shop. Compotech has been recognized as a Top Shop in both 2022 and 2023.

Beyond the data, what makes these facilities stand out? The CW team asked each of the latest honorees to share more about their companies’ histories, goals and trends in the composites industry.

In 2023, Compotech doubled its manufacturing space to accommodate the production line of the company’s newest Minator product.

The following Q&A features responses from Paul Melrose, Compotech president:

CW: What composite materials and processes do you work with?

Melrose: Primarily light resin transfer molding (LRTM), using vinyl ester and polyester resins, and various fibers such as fiberglass and carbon fiber.

CW: What end markets do you serve?

Melrose: Military and defense

CW: Reflecting back on 2023, what was your company’s biggest strength or achievement?

Melrose: Compotech’s biggest achievement in 2023 was securing $100 million in new contracts. We grew by roughly 30% and onboarded 20 new employees, growing our workforce from 27 to 47 employees. Our manufacturing space doubled in 2023 from 20,000 square feet to approximately 44,000 square feet. This expanded space is used for our new production line for Minators, a panelized building system.

CW: What goals do you have going into 2024?

Melrose: Our goal in 2024 is to broaden our customer base with our existing product lines and expand production of new solutions.

CW: How does sustainability factor into your operations?

Melrose: Compotech has prioritized sustainability by developing and producing highly energy-efficient composite buildings that replace single-use facilities, and by using materials that double the lifespan of conventional processes. Compotech’s processes result in exceptionally low scrap compared to other companies.

CW: Do you use automation in your operations?

A MultiCam CNC router cutting packaging at Compotech’s facility.

Melrose: In 2020, we invested in automation, a decision that has significantly impacted our operations and the quality of products we deliver. This investment involved the integration of six advanced robots into our production process. These robots play a crucial role in the creation of ballistic protection systems and expeditionary shelters for the U.S. Army. Their capabilities are remarkable, as they handle tasks ranging from sanding and drilling to welding and packaging of our ballistic protection panels.

These six-axis robotic arms are capable of lifting and moving up to 500 pounds, making them the perfect solution for tasks that are heavy and repetitive. The introduction of automation has enhanced our manufacturing efficiency and enabled us to focus on tasks that require human creativity and expertise.

Our decision to embrace automation is not about eliminating jobs but about replacing roles that are physically demanding and pose a high risk of injury. At Compotech, we are committed to the well-being of our employees. As a result, we have created new job opportunities within our company, such as robot operators and engineering positions. These roles come with higher wags compared to manual labor jobs, ensuring our employees benefit from this technological advancement.

Automation has been a game-changer for Compotech, enabling us to achieve precision and higher throughput in our manufacturing processes. Some of our machines can now process a month’s worth of products in just 3 days, highlighting the tangible benefits of automation in terms of productivity and efficiency.

CW: How has Compotech overcome labor shortage issues, and how does the company employ workforce development?

Melrose: Compotech’s labor market is suffering from shortages, as the unemployment rate in Maine is less than 3%, nearly an all-time low. We expected our company to grow in this environment, so we designed our manufacturing processes and our cost structure for flexibility. The manufacturing processes were designed so that a highly skilled and specialized composite technician wasn’t required to build composite parts.

New, unskilled employees can be trained and made efficient within weeks. By reducing the workforce for only value-added activities and automating many tasks, we’re able to keep the overall labor portion of our costs low, allowing Compotech to higher wages needed to attract new employees. With this model, Compotech significantly increased our head count in the face of a very challenging labor market.

Related Content

Fall events chart the course for composites

A busy fall brings industry-leading events and recognition for operations setting new benchmarks for excellence.

Read MoreFinnish boatbuilder balances history, innovation in fiberglass composites design

CW Top Shops honoree Sargo Oy shares its successes in upgrading operations from hand layup to infusion, employing low-waste manufacturing practices, research in large-format 3D printing for mold production and more.

Read MoreBucci Composites expands automotive production capabilities with facility addition, new high-ton presses

CW Top Shops recipient Bucci Composites shares an update on its facility expansion, automotive composites applications, sustainability, education initiatives and more.

Read MoreDefense manufacturer reflects on growth, opportunity in complex composite structures

Long Island-based, four-time CW Top Shops honoree GSE Dynamics cites diversification in processes, digitalization, workforce training and more on its successes over 50+ years, and looks ahead to future growth.

Read MoreRead Next

CompoTech: Designing and Supplying Turnkey Composites Technologies

At JEC World 2023, CompoTech showcased its automated fiber winding and laying technology capabilities, highlighting the company’s latest custom-built, automated fiber winding machine, with fiber placement using a FANUC six-axis robot.

Read MoreCompoTech promotes automated filament winding machine options

Custom-built, turnkey automated winding and filament placement equipment create new possibilities for manufacturers to cost-effectively produce high-strength structural carbon fiber components.

Read MoreFinnish boatbuilder balances history, innovation in fiberglass composites design

CW Top Shops honoree Sargo Oy shares its successes in upgrading operations from hand layup to infusion, employing low-waste manufacturing practices, research in large-format 3D printing for mold production and more.

Read More.jpg;width=70;height=70;mode=crop)