2014 SBIR funding solicitations are short on composites

However, the industry should note trends revealed in the areas DoD prioritizes for technology research and transfer.

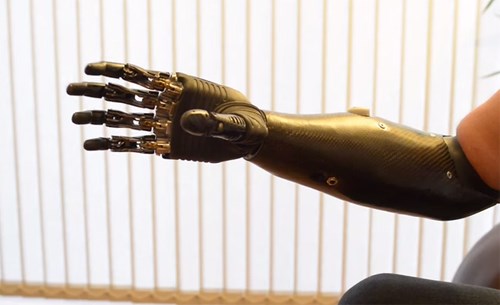

Prosthetic limbs fabricated from composites are among the SBIR-funded projects

that are garnering more attention.

Out of the 21 topics released online in the U.S. Department of Defense (DoD) fiscal year (FY) 2014.3 , only one directly lists composites. The description for “Replacement Nose Fairing Material” is listed below. Instead, most of the research topics deal with sensors, microelectronics or modeling and computing, though the Navy’s subgroup includes “Optimization of Advanced Wireless Textiles” and “Advanced Textile Manufacturing Using 3D Printing”.

For the composites industry, the take-home is to note the push to integrate sensors into everything, from cargo containers to clothing to the next generation of night vision goggles. In the case of containers — the Defense Threat Reduction Agency’s (DTRA) topic “Smart Materials to Indicate Personnel Presence in Proximity to Container” — the DoD would like to replace cameras, infrared sensors and visual inspection by guard forces with a means to maintain security that does not require staffing and is not easily disabled. The research description suggests that integrated/embedded sensors will need to detect multiple signatures, for example motion, body heat and molecular compounds emitted during breathing.

Another interesting topic is the Defense Advanced Research Projects Agency’s (DARPA) “Energy Harvesting for Next Generation Neurotechnology”. Basically the DoD wants to advance Neuroprosthetics — which already can actuate prostheses based on closed-loop sensing and computation — by replacing batteries with biomedical energy harvesting technologies. This also reflects a larger trend outside the military. Bionics are here. They are still expensive and in development, but they are no longer science fiction. Both of the devices in the videos below from and use carbon fiber composite laminates.

Prosthetics has always been a market for composites, but with advances in electronics and injured troops returning from Iraq and Afghanistan, the push to improve this technology into self-powered neuroprosthetics that are actually affordable has ramped significantly.

Finally, there is another round of funding available for awards in 2014, this one known as the DoD FY 2014.B Small Business Technology Transfer (STTR) Solicitation. Of the 13 topics included here, only DARPA’s “Revolutionary Airlift Innovation” implies composites, seeking unmanned gliders to perform cargo lift operations from ship to unsecured shore areas. The Missile Defense Agency (MDA) topic "Failure Avoidance in Microelectronics Due to Coefficient of Thermal Expansion (CTE) Mismatch of Substrates and Adhesives” reflects a large trend in the printed circuit board (PCB) industry — reportedly the largest consumer of glass fiber — to develop higher laminate performance and thermal capacity as electronics get smaller and more sophisticated. Watch for our full-length feature on that in the October issue of Composites Technology magazine.

NAVY N143-130 Replacement Nose Fairing Material

DESCRIPTION: The Nose Fairing provides hydrodynamic and aerodynamic stability during launch and flight. The Nose Fairing provides a direct interface during onload and offload of the missile while supporting the entire weight of the missile. Navy Strategic Systems Programs (SSP) desires to develop a replacement material with the following parameters:

Service Life Goal - 50 years

Nominal Thickness - 0.5 inch

Tensile Strength – Longitudinal > 8.0 ksi Property quantified to B-Basis**

Tensile Strength – Hoop > 2.5 ksi Property quantified to B-Basis**

Bending Strength – Longitudinal > 5.0 ksi

Shear Strength > 1.6 ksi Property quantified to B-Basis**

Internal material damping - Loss Factor = 0.01 or higher

Radio Frequency Transparent in the GigaHertz region of the electromagnetic spectrum (EM) spectrum

Density - 0.58 gm/cc.

Manufacturability – Must be able to form into a complex curvature (doubly curved shell of revolution)

**At least 90 percent of the population of values is expected to equal or exceed the B-basis mechanical property allowable, with a confidence of 95 percent.

REFERENCES:

1) Payload Fairing. http://en.wikipedia.org/wiki/Payload_fairing

2) Nose Fairings on Rockets and Ballistic Missiles. http://www.gpo.gov/fdsys/pkg/GPO-CRPT-105hrpt851/pdf/GPO-CRPT-105hrpt851-2-6.pdf

KEYWORDS: Strategic Missiles; Composite Materials; Materials Development; RF transparent structural materials; Ultrastrong materials; Nanocomposites

TPOC: Roderick Santander

Phone: (202)433-5839

Email: roderick.santander@ssp.navy.mil

2nd TPOC: David Olson

Phone: (202)433-5807

Email: David.Olson@ssp.navy.mil

Related Content

On the radar: Reusable launch vehicles, hypersonics make space more accessible

CFRP has become key to targeting efforts in reusing components like rocket stages, as well as the development of reusable hypersonic testbeds and spaceplanes, for increasing space commercialization.

Read MoreCall for abstracts: CW Tech Days to explore high-temperature composite solutions

The fall 2025 installment of CW’s Tech Days online event series will cover high-temperature composite solutions for defense and space applications.

Read MoreCarbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

Read MoreRevolutionizing space composites: A new era of satellite materials

A new approach for high volumes of small satellite structures uses low-CTE, low-cost CFRP cellular core, robust single-ply skins and modular panel systems to cut lead time, labor and cost for reflectors, solar arrays and more.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More