Weaving

COMPOSITES+POLYCON 2009 Showcase

Despite the deepening recession, composites pros returned to the show in its new time slot to explore the wealth of products and services collected here.

Read MoreThermoplastic composites: Inside story

Reinforced thermoplastics buy their way into structural aircraft interior components.

Read MoreInside R and D: A-VaRTM takes flight in Japan

Tests show out-of-autoclave process can reduce costs on new regional jet.

Read MorePultruding cost out of aerospace parts

Design-for-manufacturing effort proves to be cost-effective for carbon/epoxy airfoil on expendable UAV.

Read MoreOne-piece molded truck body uses customized resin formulation

When General Motors Corp. (Flint, Mich. ) opted to update its small Astro cargo van in 2007 concurrent with the introduction of new Colorado and Canyon light truck platforms, customers talked and GM listened.

Read MoreNAIA 2009 show highlights

The Detroit auto exhibition’s hybrid and electric vehicle introductions underscore the need for lightweighting with low investment cost, which composites can provide.

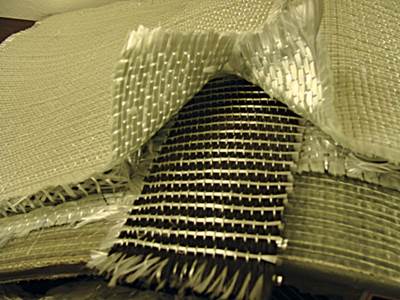

Read MoreFiber reinforcement forms

Rovings, the most common form of glass, can be chopped, woven or otherwise processed to create secondary fiber forms for composite manufacturing, such as mats, woven fabrics, braids, knitted fabrics and hybrid fabrics. Rovings are supplied by weight, with a specified filament diameter. The term yield is commonly used

Read More787 integrates new composite wing deicing system

The composite wing leading edge on Boeing’s Dreamliner features an integrated heating element that incorporates a sprayed metal conductive layer within the laminate stack.

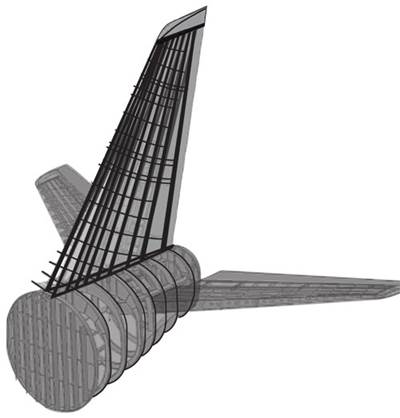

Read MoreUnmanned rotorcraft passes stringent German Navy shipboard tests

CAMCOPTER’s high strength-to-weight ratio is made possible by composite materials.

Read MoreWind Blade Manufacturing: Cost-efficient materials-based strategies

The wind blade’s four key elements — the root, the spar, the aerodynamic shell or fairing, and the surfacing system — have present unique manufacturing challenges that must be met with carefully selected composite material systems and molding strategies.

Read More