Space

World's first all-carbon RV

Built without mechanical fasteners and at approximately half the weight of conventional products, the CR-1 is impressive and designed by an impressive team.

WatchOrbital-ATK marriage a sign of the times?

The merger of Orbital and ATK's Aerospace and Defense groups indicates that companies are positioning themselves to take advantage of the new public/private space market.

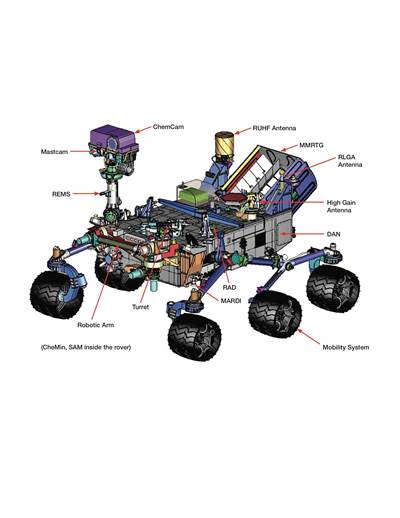

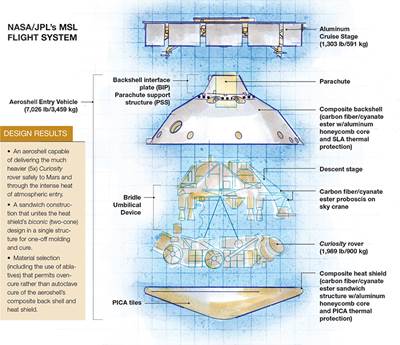

Read MoreThe Curiosity Mars rover: Descent stage composites

Apart from the aeroshell that protected the Curiosity rover during its months in space and Mars descent sequence, only a few other parts of the mission’s descent stage were made from composite materials. Here, HPC identifies and describes them.

Read MoreComposites carry the Curiosity rover to a safe Mars landing

From launch to touchdown, composites performed in flight and stuck the landing!

Read MoreCarbon fiber cryotank angles for a place in launch systems

Boeing has manufactured two carbon fiber cryotanks that are being evaluated by NASA for use in heavy-lift launch systems. They offer 30 weight and 25 percent costs savings.

Read MoreUAVs may deliver Internet access

Facebook is considering use of unmanned aerial vehicles (UAV) to bring Internet access to remote areas. The composites industry could be among the beneficiaries.

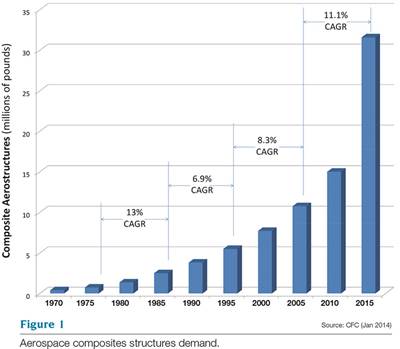

Read MoreThe market for OOA aerocomposites, 2013-2022

In the coming decade, out-of-autoclave technologies will increase composites penetration into primary flight structures.

Read MoreNo-oven, No-autoclave (NONA)

Room-temperature cure epoxy composites with a 400°F Tg, comparable properties vs. commercial systems without external heat or post-cure, and offering reduced cost and cycle time. Really?

WatchBMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

Read MoreMaterials Genome Initiative: Impact on Composites

Promising outlook offered by hands-on source.

Read More