The Curiosity Mars rover: Descent stage composites

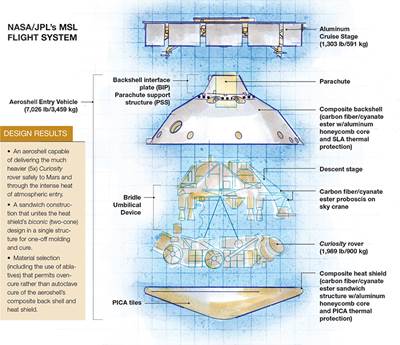

Apart from the aeroshell that protected the Curiosity rover during its months in space and Mars descent sequence, only a few other parts of the mission’s descent stage were made from composite materials. Here, HPC identifies and describes them.

Apart from the aeroshell that protected the Curiosity rover during its months in space and Mars descent sequence, only a few other parts of the mission’s descent stage were made from composite materials. (For details of the aeroshell’s composites design, see “Composites carry the Curiosity rover to a safe Mars landing” under Editor’s Picks,” at top right.) Eric Oakes, a materials engineer in NASA’s Jet Propulsion Laboratory (JPL). Provided the following data:

The proboscis on the skycrane features a set of structural M55J/BCTA-1A prepreg tubes that held the ground sensing radar on the skycrane. These tubes were bonded to primed titanium end-fittings with EA 9392 room-temperature cure paste adhesive, supplied by Henkel Aerospace (Bay Point, Calif.), which offers exceptional shear strength at high temperatures.

The parachute closeout cone lid is a sandwich construction, with a circular (36-inch/91.4-cm diameter, 0.125-inch/0.32-cm thick) aluminum vented honeycomb core panel bonded between M55J/BTCy-1A faceskins. The lid was installed at the top of the back shell. During descent, the parachute canister “shot out right through the lid,” Oakes says. The lid design needed to meet launch loads and changing pressure loads — “but not be too strong to slow down the velocity of the parachute canister, since that could risk interference with the opening of the parachute.” Further, when it pushed through the back shell, the lid had to “come out cleanly and fly away,” Oakes says, “so the piece was not floating around to possibly go through the parachute or damage any other parts.”

On the rover itself, composites were employed to build three antenna radomes (see image, at right), using TenCate Advanced Composites’ (Morgan Hill, Calif.) Astroquartz quartz fiber/BCTy-1A cyanester prepreg, which Oakes describes as having a “heritage from the Deep Impact 2005 mission to a comet and beyond.” The material was ideal, he notes. “We know the values are constant, we know the loss tangent of that material, we know what its properties are.”

Further, the heat exchangers that control the rover’s temperature on Mars are also sandwich constructions. Hexcel’s trademarked HexWeb HRH 10 Nomex aramid fiber/phenolic composite honeycomb panels — 0.125-inch/3-mm thick, 6 lb per ft3/96 kg per m3—are bonded between 7075-T73 aluminum alloy facesheets. Reportedly, these panels can withstand a temperature gradient of 201°C/394°F with temperature extremes ranging from a low of -111°C/-168°F on the outside to 90°C/194°F on the inside. The honeycomb cells needed to be vented, but the core material was not supplied in that form, so Oakes “had a tool made with evenly spaced knife blades to cut a small slit in the tops of each of the honeycomb cells.”

After the honeycomb core was bonded to the inside faceskins, Oakes says that JPL “crushed a product called Aerogel into the honeycomb” to block heat from passing through the cells. Invented in the 1930s and refined by NASA, Aerogel is the lightest and lowest density solid known to exist, weighing a mere 0.00011 lb/in3. After the honeycomb cells were filled, the outside aluminum skin was bonded onto the now-vented core. Aluminum tubes bonded to the panels carried Freon refrigerant made by DuPont Chemicals & Fluoroproducts (Wilmington, Del.) through the heat exchanger.

The panels were bolted directly to the rover chassis and a multi-mission Radioisotope Thermalelectric Generator (MMRTG), the nuclear source for the rover’s energy, was installed between the panels, bolted to the rover but not connected to the panels.

Related Content

Composite products designed for efficiency, performance and sustainability

CAMX 2025: Whether through weight reducing or strength enhancements, 3M designs its microspheres, ceramic fibers, films and LSP materials and composite resins to meet its customers application demands.

Read MorePerformance resins, putties and structural adhesives

CAMX 2025: Scott Bader illustrates its local and global materials supply availability backed by technical support, as well as a novel composite panels development with Armacell.

Read MoreBelzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

Read MoreComposite, adhesive and core solutions focus on performance, reducing carbon footprint

JEC World 2025: Gurit celebrates 190 years with a display of its product variety — from Spabond 400, resins, prepregs and Gurit PET to BalsaFlex, Opticore and other core systems.

Read MoreRead Next

Composites carry the Curiosity rover to a safe Mars landing

From launch to touchdown, composites performed in flight and stuck the landing!

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More