Resins

Composites extend service of oil and gas pipelines

Corrosion-resistant aramid fiber/thermoplastic liner gives new life to deteriorating steel subsea pipelines.

Read MoreResins for the Fast Zone

An automotive supplier must have the ability to produce a composite part in a minute, or at least in minutes — not hours or days, the norm for composites in most other industries. Meeting that part-per-minutes goal is a huge hurdle that a few composite fabricators have cleared, and many more are involved in development efforts, with OEM or Tier partners. ÂÌñÏ×ÆÞ reviews how resin suppliers have evolved their products for this critical market.

Read MoreOvermolding expands PEEK’s range in composites

A new polymer and a hybrid process enable production of complex, high-load-capable, fiber-reinforced brackets and clips in minutes.

Read MoreComposite engine piston cylinder housings

Phenolic BMC could replace aluminum in car/motorcycle engine housings.

Read MoreThermosets vs. thermoplastics: Is the battle over?

Dale Brosius, the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI) and a regular CW columnist, sees a shift in the industry from infighting between proponents of thermoset and thermoplastic composites to a healthier competitive atmosphere that serves to make composites overall more competitive with legacy materials.

Read MoreTires that never go flat

SciTech Industries and Rapid Composites develop high-volume production tires that use glass fiber/PET composite springs instead of innertubes and compressed air.

Read MoreThermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

Read MoreThermoplastic composites: European consortia, galore!

In addition to the Thermoplastic Composites Research Center (TPRC, Enschede, The Netherlands) — see our article focused on TPRC, titled "Thermoplastic composites technology: A view from Europe" under "Editor's Picks, at top right — there are many other European consortia, comprising private industry, university and government entities, which share the goals of exploring composites materials and methods for manufacturing them, including those with thermoplastic matrices. Here's a sampling.

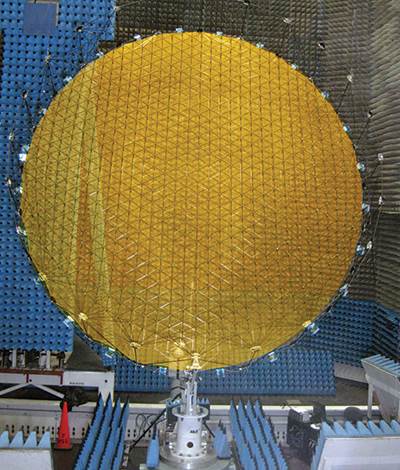

Read MoreIn-orbit-deployable radar dish

Aramid/PEI delivers flexibility, strength and precision for space-based reflector

Read MoreUnderstanding the influence of fiber orientation on structural analysis of fiber-filled parts

The effect of fiber orientation on material properties is a key way the injection molding process impacts mechanical performance. Doug Kenik and Angie Schrader of the Design, Lifecycle & Simulation product group at Autodesk (Waltham, MA, US) illustrates two ways fiber orientation influences the structural behavior of fiber-filled parts and discuss the need for a bi-directional approach to design and analysis.

Read More