Resins

DSM thermoplastics featured in CNG and hydrogen tanks

Tanks developed by Belgium-based Covess that use a polyamide liner and outer layer offer up to 70 weight savings in a 40-liter tank for compressed natural gas or hydrogen storage.

Read MorePMI foam core outperforms honeycomb in infused nose landing gear doors

The results of Airbus (Toulouse, France) subsidiary Composite Technology Centre GmbH (CTC, Stade, Germany) studies in 2013 to find more productive but less costly methods of fabricating carbon fiber-reinforced polymer (CFRP) sandwich constructions.

Read MorePlastiComp introduces carbon-glass hybrid LFT

The new hybrid composite pellet products combine long glass fiber and long carbon fiber together, bridging the performance gap between either fiber used alone.

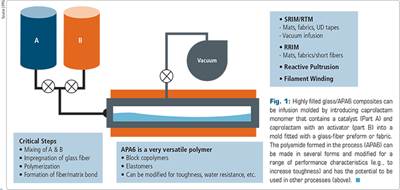

Read MoreInfusible thermoplastics via in-situ polymerization

A low-viscosity monomer that can be polymerized in the mold enables infusion of continuous glass fiber with polyamide 6.

Read MoreTeijin's high-speed composites manufacturing process: Still a mystery

Since Teijin's 60-second carbon fiber molding process was announced in 2011, we've heard little about it. It would be great for the industry if it could bear fruit soon.

Read MoreUltrasound evaluation of prepreg impregnation levels

The Ultran Group has developed non-contact ultrasound (NCU) that can accurately assess prepreg level of impregnation (LOI) with implications for out-of-autoclave processing, inline quality control and even automated tape laying.

Read MoreLeichtbau ist hybridbau

Integrating multiple materials and functions for lightweight construction in the German automotive industry.

WatchSAMPE Seattle 2014 Report

The Society’s reconfigured Spring advanced materials event in Seattle, Wash., attracts speakers, exhibitors and attendees in large numbers and international dimensions.

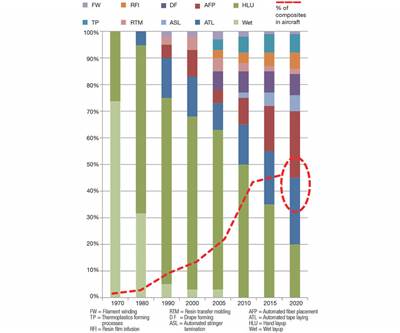

Read MoreThermoplastics in Aerospace Composites Outlook, 2014-2023

Capable of volume production, thermoplastic composites will gain new market share in the aerospace industry.

Read MoreAre LFRT composites key to auto adoption?

Long carbon fiber-reinforced thermoplastics don't pack the punch of continuous carbon fiber, but they might help spread use of composites in automotive.

Read More