Resins

Reformable composite equestrian saddle

This carbon fiber/polyethylene terephthalate (PET) saddle tree features an intralaminate heating element that enables horse owners to reconfigure saddle shapes as horses grow, greatly reducing long-term saddle-fitting costs.

Read MoreSlideshow of SPE ACCE 2015

A look at the 15th edition of SPE’s Automotive Composites Conference & Exhibition (ACCE).

Read MoreAVANCO: Driving the industrialization of CFRP structures

The AVANCO Group is producing high-quality CFRP parts into a wide array of applications from six production facilities in Germany and the US.

Read MoreSPE ACCE 2015 show report

Was this the year, finally, for the big break-through for automotive composites? Maybe, depending on to whom one talked or the presentation one heard.

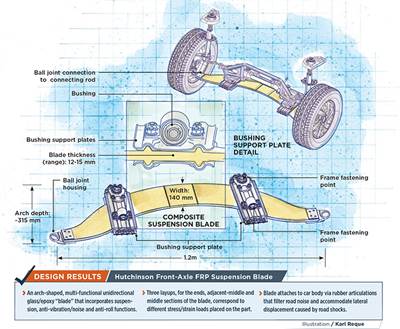

Read MoreAutomotive front axle: A glass act

The development of glass-fiber reinforced car axle is a sign of the new, expanded role composites will play in the design of future automobiles.

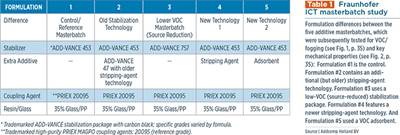

Read MoreVOC reduction strategies for LFRT composites

Additives supplier seeks novel methods to limit VOC emissions from long-fiber-reinforced thermoplastics.

Read MoreAeroengine Composites, Part 2: CFRPs expand

Proven in fan blade/case applications, carbon fiber-reinforced polymers migrate to previously unanticipated destinations nearer the engine “hot zone.”

Read MoreAutomotive composites: Thermosets for the fast zone

Epoxies continue to be developed for faster cure to meet automotive production rates.

Read MoreComposite brackets for life-of-aircraft service

Reinforced PEEK molding formulated for jet fuel/hydraulic fluid immersion.

Read MoreOuter space: The “final frontier” is exciting again!

CW contributor Dale Brosius, a composites industry consultant and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI), points to evidence that the composites industry will, once again, be the beneficiary of renewed drive for space exploration.

Read More