Ketones

Boston Materials manufacturing line increases composite material production capacity

Boston Material’s new 60-inch-wide roll-to-roll manufacturing line increases production capacity of Z-axis carbon fiber materials to more than eight million square feet per year.

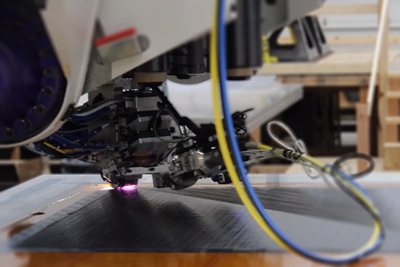

Read MoreVictrex, Electroimpact achieve thermoset AFP speeds using thermoplastics

Using Electroimpact’s AFP technology and Victrex’s low-melt PAEK prepreg tape, the companies report laydown speeds of 4,000 inches per minute.

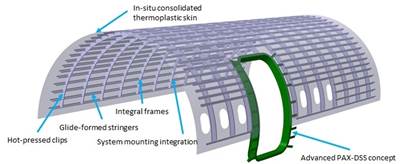

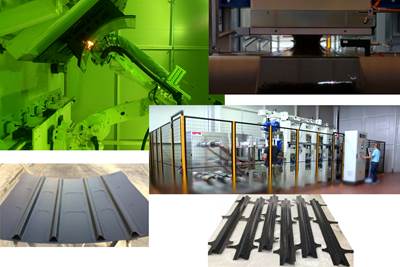

Read MoreManufacturing the upper half of the Multifunctional Fuselage Demonstrator (MFFD)

Proving industrial reliability for low-cost thermoplastic composites production using AFP in-situ consolidation, as well as continuous ultrasonic and resistance welding.

WatchMultilayer thermoplastic tapes, AFP and resin infusion for more democratic composites

Novotech advances new materials and more affordable automated processes for small aircraft and beyond

WatchEpisode 35: Lisa Ketelsen, Covestro

CW Talks visits with Lisa Ketelsen, head of thermoplastic composites and CEO of Maezio at Covestro. Ketelsen talks about her path to Covestro and the Maezio product line, Maezio’s attributes and applications, and how she sees thermoplastic composites evolving in the marketplace.

ListenInfinite Material Solutions presents water-soluble support material for 3D-printing capabilities

AquaSys 180 is compatible with high-temperature thermoplastics and holds an advantage for the Fused Filament Fabrication (FFF) 3D printing process.

Read MoreAviation research program kicks off for continuous complex composite profiles

InPro project combines blow molding technology with Continuous Compression Molding (CCM) process for efficient, sustainable continuous composite profile production.

Read MoreMoving forward on the Multifunctional Fuselage Demonstrator (MFFD)

Clean Sky 2’s MFFD program continues to move toward its goal of delivering a welded, thermoplastic composite fuselage demonstrator using next-generation manufacturing processes.

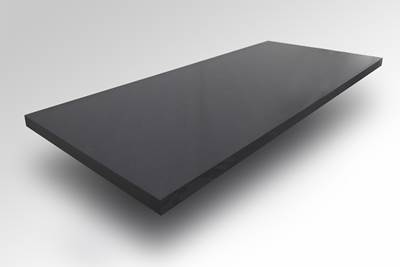

Read MoreVictrex, Daher, attain next-gen thermoplastic aircraft panel milestone

The developed panel is a 176-ply laminate, 32-millimeter-thick composite structure and uses Victrex AE 250 PAEK-based thermoplastic composites.

Read MoreZortrax develops groundbreaking 3D Printing technology

High-performance parts are made out of two blends of PEEK filament via dual extrusion on Endureal industrial 3D printer.

Read More