Aviation research program kicks off for continuous complex composite profiles

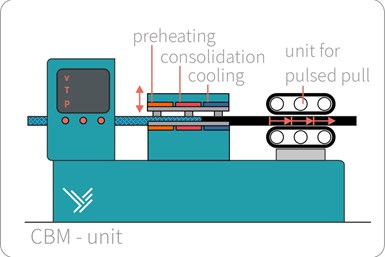

InPro project combines blow molding technology with Continuous Compression Molding (CCM) process for efficient, sustainable continuous composite profile production.

Photo Credit: herone GmbH

Funded by the German Federal Ministry for Economic Affairs and Energy (BmWi) as part of its civil aviation research program, herone GmbH (Dresden, Germany), a spin-off from the Technical University (TU) Dresden, announces the kick-off of its three-year InPro research project for the continuous production of thermoplastic composite hollow profile structures with the help of an interval hot press technology, the Continuous Blow Molding (CBM) process. The project will extend herone’s discontinuous production capabilities with partners HPF GmbH & Co. KG (Saxony, Germany) and the Institute for Lightweight Engineering and Polymer Technology (ILK) at TU Dresden.

According to herone, the CBM process serves as the project’s basis. The patented, semi-continuous approach combines blow molding technology with a Continuous Compression Molding (CCM) process to enable the continuous production of composite hollow profiles. This process, says herone, is said to be especially important in high-stress areas, such as load introduction locations. Further, the process is said to be more efficient and saves on resources, thus lowering environmental impact.

Within the research project, the CBM technology to process high-performance thermoplastics (such as PEEK polymers, PPS or PPA) will be further developed and combined with the injection molding technology to allow for additional functionalization of the composite profiles. The company adds that subsequent injection molding step enables the integration of functional elements (e.g. gears, levers, sealing surfaces, integral composite threads) into the basic component via form-fitting connections or a combination of form-fitting and cohesive joints. Targeted components include tension-compression struts, drive shafts as well as media-carrying storage systems like liquid hydrogen pipes.

InPro will end in 2023 and is supported by international partners Victrex (Thornton Cleveleys, U.K.) and Boeing (Chicago, Ill., U.S.) for deployment.

Related Content

-

ASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

-

Life cycle assessment in the composites industry

As companies strive to meet zero-emissions goals, evaluating a product’s carbon footprint is vital. Life cycle assessment (LCA) is one tool composites industry OEMs and Tier suppliers are using to move toward sustainability targets.

-

Partners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.