Ketones

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreStratasys collaborates with Lockheed to qualify composite materials for space, aviation end-use parts

Report made public by Metropolitan State University of Denver delivers qualification data for Antero 840CN03 for additively manufactured end-use parts requiring high thermal and chemical resistance, and ESD properties.

Read MorePlant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

WatchRoboze reveals ceramic-filled Helios PEEK 2005 filament to the 3D printing sector

Ceramic reinforcement proves an ideal candidate for applications that require lightness, mechanical strength, heat resistance and highly complex geometry specifications.

Read MoreCygnet Texkimp thermoplastic lab line build supports composites innovation

Direct Melt Impregnation Thermoplastic Line to enable faster development of composites technology in automotive, aerospace, construction and energy markets through dedicated customer trials.

Read MoreRoboze raises funds for composites industrial 3D printing platforms

A diverse pool of domestic and international investors aid in the further acceleration of R&D for ultra-precise 3D printing of carbon fiber PEEK and other polymers.

Read MoreAIM3D multi-material 3D printer targets precise, cost-effective polymer processing

Extrusion 3D printer offers considerably faster build rates and can print up to three different materials in parallel for metals, ceramics and high-temperature plastics such as PEEK and PPS with or without fiber filling.

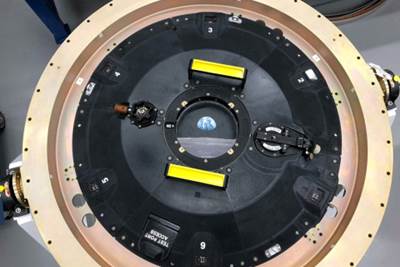

Read MoreAON3D, Astrobotic to send 3D-printed parts to the moon

The Peregrine Lander will carry thermoplastic parts printed via AON3D’s high-temperature industrial 3D printer that meet demanding space requirements and cut the vehicle’s weight by half.

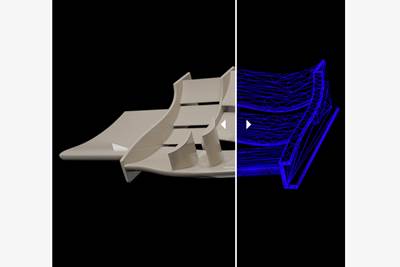

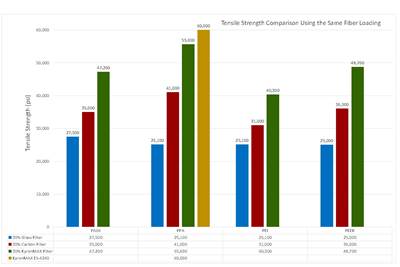

WatchShort carbon fiber compounds expand reach of thermoplastic composites

With fiber weight fractions of up to 50% and an array of thermoplastic matrices available, injection molding compounds are expanding composites’ capabilities.

Read MoreSolvay completes South Carolina facility installation, adds to U.S. thermoplastic composite capacity

Facility development is fueled by increasing energy, aerospace and automotive demand, and will manufacture UD PVDF, PPS and PEEK tapes.

Read More