AIM3D multi-material 3D printer targets precise, cost-effective polymer processing

Extrusion 3D printer offers considerably faster build rates and can print up to three different materials in parallel for metals, ceramics and high-temperature plastics such as PEEK and PPS with or without fiber filling.

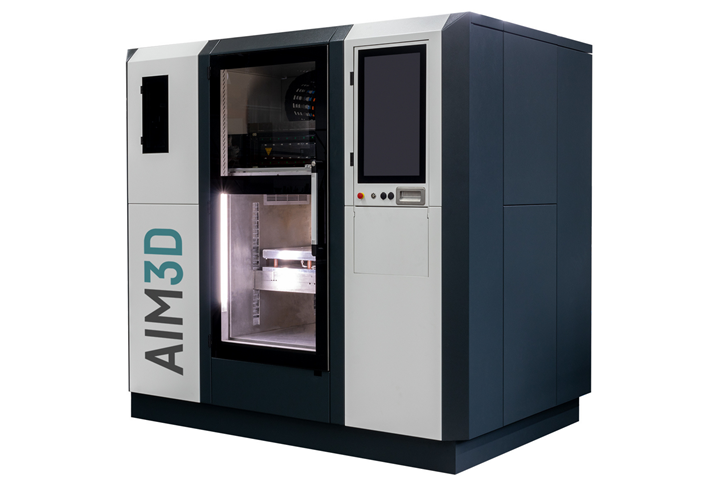

ExAM 510 multi-material printer. Photo Credit, all images: AIM3D GmbH

(Rostock, Germany), a manufacturer of multi-material 3D printers, has developed a 3D printer for the composite extrusion modeling (CEM) process, which combines metal injection molding with additive manufacturing (AM). The ExAM 510 boasts a larger build area, higher precision and faster build rates, AIM3D says, and is a multi-material printer for AM that can print up to three different materials in parallel, including pellet-based processing of high-performance plastics such as PEEK and PPS. ExAM 510 is planned to be ready for series production in time for Formnext 2022, according to the manufacturer.

The latest addition to Rostock’s product lineup, the ExAM 510 is a performance-enhanced version of the previous ExAM 255. It can process up to three materials; this allows for two building materials and a support material. The extended build platform at 510 x 510 x 400 mm reportedly enables a multitude of applications. Build area can be heated up to 200ºC in order to reduce stresses in the component and to process high-performance materials. It also features a considerably increased build rate, depending on the material, of up to 250 cm³/h (when using a 0.4-mm nozzle).

Moreover, the ExAM 510 concept enables increased precision of printed components, with the objective of taking advantage of AIM3D’s patented extruder technology. This extruder class offers an output up to 10 times higher than standard filament extruders, the company notes. Further, the use of linear motors and a stable mineral cast bed makes highly precise operation possible even at high speeds.

Coolant distributor nozzle from Schaeffler (Herzogenaurach, Germany), 3D printed with the CEM process and made of PPS GF 40 Type Fortron 1140L4 injection molding pellets from Celanese (Dallas, Texas, U.S.).

The use of a wide range of materials is one particular appeal, especially for composites fabricators. AIM3D equips the machine with a heated process chamber specially designed for high-temperature plastics. This enables the processing of high-temperature plastics such as PEEK, PEI, PSU, PPS, with and without fiber filling, directly in pellet form.

Inexpensive recycling is also a capability. According to the manufacturer, a material can be tested in 1-2 working days and established for production in 5-10 working days. AIM3D uses PEEK as an example: if the price for PEEK filament is around €700/kg used on conventional AM machines, the ExAM 510 can use PEEK pellets, as deployed in convential injection molding. The market price of around €50/kg for PEEK pellets amounts to only 7% of comparable material costs or a cost reduction by a factor of 14. This opens up new dimensions in terms of cost efficiencies, AIM3D concludes.

|

Range of materials for the ExAM 510 |

|

|

Plastics |

PETG, PP, PA6, POM, PPS, PEEK, PEI, TPE |

|

Reinforced Plastics |

PA6 GF30, PA6 GF40, PA6 MF60, PBT GF30, PA12 GF30, PA6 GB, PA6 CF15, PPS GF40, PEEK CF, PEEK Si |

|

Metals |

316-L, 17-4PH, 8620, 42CrMo4, 304, 420 W, WcCo, Ti64, Cu99 |

|

Ceramics |

Al2O3, ZrO2, SiC, Si3N4 |

Areas of application for high-performance polymer materials can be found in automotive, medical technology or aerospace, end markets in which AIM3D’s pilot customers are based in. Reinforced plastics such as PA6 GF30, PPS GF 40, PEEK and PEI can specifically be used for applications like coolant technology, automotive and ESD housings. Aluminium and zirconium oxide, silicon carbide and silicon nitride ceramic materials are applicable for chemical process technology, high-voltage isolators and thermally stressed components. Metals like stainless steel, copper, tool steels, tungsten and tungsten carbide can be used with the ExAM 510 as well.

Related Content

Optimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MoreReinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

Read MoreFIDAMC expands composites R&D into new markets and advanced manufacturing centers

Pioneering technocenter advances RTM, thermoplastic composites, additive manufacturing, microwire, novel lighter weight LSP and more.

Read MoreMulti-material, self-sensing, 3D-printed scoliosis braces

Startup Fited and Brightlands Materials Center have developed a lighter weight, thinner CFRP corrective brace, including pressure sensors made from continuous carbon fibers.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More