Ketones

Teijin carbon fiber-reinforced thermoplastics qualified for aerospace applications

Collins Aerospace deemed Teijin Ltd.’s Tenax thermoplastic woven fabric and consolidated laminate materials suitable for large-scale production of structural components.

Read More3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

Read MoreHexcel launches electrically conductive PEKK-based carbon fiber material

HexPEKK EM is a high-performance material for additive manufacturing that meets electromagnetic shielding, radiation absorption requirements.

Read MoreHexcel applies additive manufacturing to unmanned aerial vehicle systems

Hexcel’s HexAM process produces stiff, lightweight and complex components that are often too expensive or impossible to produce.

Read MoreFibre Extrusion Technology FET-100 series reaches $20 million in sales

The multi-functional melt spinning system facilitates the development of precursor synthetic textile materials, as well as biodegradable composite materials.

Read MoreCAMX 2020 exhibit preview: AGC Chemicals

AGC Chemicals Americas' mPLASTICS are new fluoropolymer-modified compounds to enhance the performance of carbon fiber-reinforced thermoplastic composites.

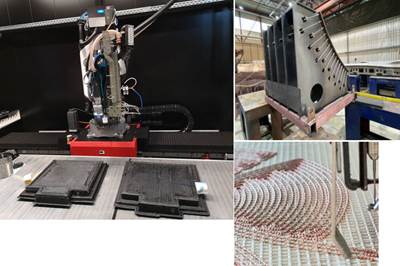

Read MoreElectroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell

The Scalable Composite Robotic Additive Manufacturing (SCRAM) system 3D prints with continuous fiber tape or filament and seamlessly swaps end effectors for large-scale pellet deposition and CNC machining.

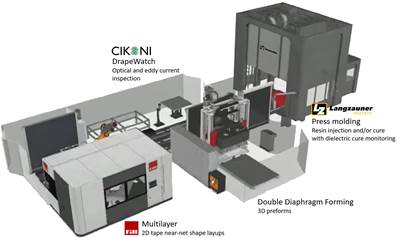

WatchSwinburne University and CSIRO's Industry 4.0 Testlab for Composite Additive Manufacturing

Australia and Germany collaborate to build Composites 4.0 production line for competitive advantage in next-gen manufacturing and workforce.

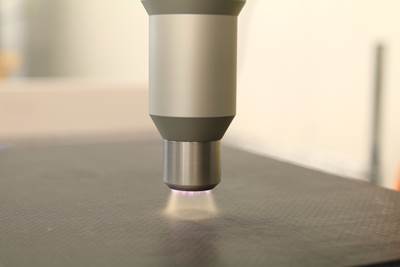

WatchSurface treatment for adhesive bonding: Thermoset vs. thermoplastic composites

According to BTG Labs, common surface treatment methods like abrasion and plasma treatment work best for different materials.

Read MoreThe untapped potential in Formula 1 composite manufacture

Formula 1’s midfield teams are struggling to bridge the gap to their better resourced frontrunning counterparts. Could Industry 4.0 composites manufacturing automation level the playing field?

Read More