Infusion

Advances in sizings and surface treatments for carbon fibers

As carbon reinforcements find new applications, unfamiliar processes and resin systems make sizing and treatment surprisingly hot topics.

Read MoreParts consolidation key to lower cost composites

Reducing part count creates new engineering challenges.

Read MoreSchooner features carbon fiber masts, booms, spreaders

When Lion's Whelp, built by Portland Yacht Services (Portland, Maine, U.S.A.) embarked on its inaugural cruise, even seasoned marine observers saw a 65 ft white schooner, reminiscent of the early 20th century's Alden Schooners, complete with spars authentically detailed from wood with traditional brass fittings. But

Read MoreHow Are Composite Bridges Performing?

Ongoing monitoring and inspection demonstrates that composite bridge decks meet or exceed expectations.

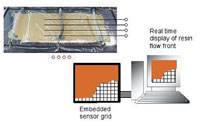

Read MoreLiquid Composite Molding Achieves Aerospace Quality

Improvements in materials, tooling and process control bring RTM and VARTM into the realm of aerospace components.

Read MoreRygerkattall — carbon fiber composite passenger ferry

Shipbuilder Brødrene Aa (Hyen, Norway) recently launched the Rygerkatt, an all-carbon fiber composite passenger ferry, built for Norway's largest passenger ferry operator, Rodne & Sønner.

Read MoreEurope's Infusion Pioneer Simplifies Process With Bottom Up Approach

Yacht builder's computer-designed method yields vacuum infusion without technical confusion.

Read MoreRV manufacturer converts to all-composite motorhome shells and floors

Since 1971, Trail Wagons - Chinook RV Inc. has built motorhomes with one-piece, molded fiberglass shells at its 115,000 ft2 plant in Yakima, Wash, U.S.A. Claiming that the shell design is essential to RV structural integrity, ease of maintenance and weather resistance, the company offers the U.S. RV industry's only

Read MoreComposites Open Road To Innovation In India

Railway and automotive applications point the way to composite mass production.

Read MoreFighting Ships Augment Combat Readiness With Advanced Composites

Navies adopt composite materials for stealth and speed.

Read More