Infusion

Recyclable epoxy proven in HP-RTM

Recyclamine hardener performs well in global processing trials and cradle-to-cradle recycling demo.

Read MoreIs the market ready for another widebody aircraft?

This past week, the Airshow China 2016 event was held, from November 1 – 6 in Zhuhai, China. A notable outcome from the show, reported in several media outlets, was that Russia’s United Aircraft Corp. (UAC) and the Commercial Aircraft Corporation of China (COMAC) have advanced their plans for their collaborative twin-aisle widebody aircraft.

Read MoreCAMX 2016 Show Report

The 3rd annual joint ACMA/SAMPE-sponsored trade event comes to Anaheim with an exhibition and conference program attractive to professionals across the composites world.

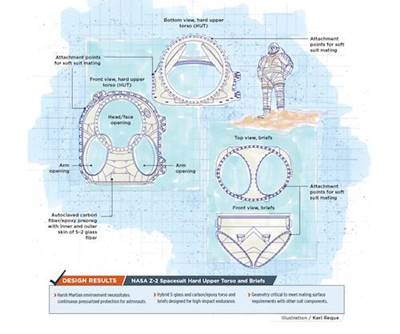

Read MoreOn Mars, not just any suit will do

NASA seeks impact resistance in next-generation space suit.

Read MoreComposites enable portability in driving simulator

FRP design enables portable, light-tight, enclosure with an image-projection-grade inner surface.

Read MoreClear Carbon & Components: Bristol, RI, US

Breaking barriers in process and complexity, this agile manufacturer is gaining renown as a composites problem solver and champion of Class A cosmetic surfaces.

Read MoreOshkosh’s AirVenture 2016 included a big infusion event

The big annual airshow featured the on-site infusion of complete aircraft fuselages for two kit aircraft.

Read MoreHuntsman, Acciona collaborate on all-composite lighthouse

The first-ever all-composite lighthouse is now installed at the port of Valencia in Spain.

Read MoreFine-tuning fiberglass: Smart fiber sizing

Some insights into those proprietary chemistries that can customize performance at the fiber/resin interface.

Read More