Design & Tooling

Toray introduces high tensile modulus carbon fiber and thermoplastic pellet

With a carbon fiber diameter of 7 microns, the Torayca T series balances cost performance with a high tensile modulus.

Read MoreCoriolis Composites and Edixia develop inline inspection for AFP

Video and discussion of how the sensor and software operate to boost composites productivity

WatchMagnum Venus products launches fusion filament winder

Ideal for winding pressure vessels, the Fusion filament winder is a compact, adaptable design.

Read MoreAnomalies force Virgin Orbit to terminate LauncherOne test

Despite the termination, the test flight provided data necessary to make adjustments for future launches.

Read MoreVertical Aerospace used Plyable to go from CAD to first flight in less than 90 days

Composite tooling specialist’s online portal, distributed manufacturing network and automated tool design helped optimize CFRP molding tools and timeline.

Read MoreExact Metrology presents RS-SQUARED area scanner

Manufactured by Hexagon, the 3D white light scanner is designed for high-speed, portable scanning of parts and surfaces.

Read MoreCapture 3D introduces ATOS Q 3D scanning technology

Capture 3D adds a high-tech, compactly designed ATOS Q to its ATOS product line of blue light 3D scanners.

Read MoreSimulation software leveraged for rotor blade project

Seoul National University uses Analyswift’s composite simulation software, VABS, for more accurate design and analyses in the university’s experimental evaluation of a SNUF rotor blade.

Read MoreJEC Group announces 2020 Innovation Awards winners

The 13 winners were announced during a virtual ceremony on May 13.

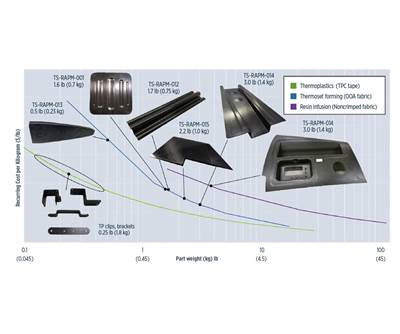

Read MoreRevolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

Read More