Design & Tooling

Contact-less microsensor targets real-time NDT for composite structures

RVmagnetics’ MicroWire self-monitors composite structures via embedding during the production process. It improves safety, control and real-time data for predictive maintenance.

WatchBBG presents self-closing HP-RTM molds for CFRP compact hydrogen tank production

The autonomous concept, sufficient for series production, enables lower investment costs. Up to 15 cylinders can be produced simultaneously per operation.

Read MoreJiangsu Hansu launches high-performance UD composite tapes

Continuous carbon fibers incorporate SABIC’s ULTEM powder, which increase high-performance and potential for aerospace applications.

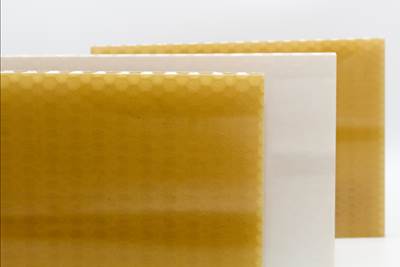

Read MoreEconCore, Toray and Bostik collaborate on FST-qualified thermoplastic honeycomb panels

Developed for mass transportation applications, including aircraft interiors, the material improves upon the cost, sustainability and versatility of conventional sandwich layup.

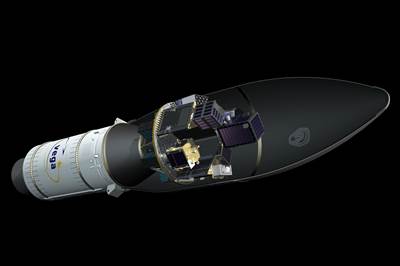

Read MoreVega VV16 rocket launches with Bercella composites dispenser structure onboard

The CFRP dispenser structure, developed for the Small Spacecraft Mission Service (SSMS), was successfully launched for the European Space Agency.

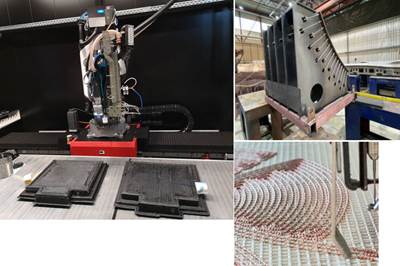

Read More3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

Read MoreUsing nondestructive testing to inspect, repair carbon fiber bicycles

An Oregon-based bicycle inspection and repair shop uses an Olympus ultrasonic thickness gage to evaluate and fix structural damage.

Read MoreAll-composite EV wheel moves to next development phase

U.K. consortium partners’ ACRIM II project aims to develop a low-cost, lightweight, all-composite wheel for electric vehicle applications.

Read MoreThermwood demonstrates vertical layer print additive technology

The new approach for large scale 3D printing was validated via Thermwood’s LSAM system and printed parts up to 5 by 10 by 10 feet.

WatchCollaborative R&D project aims to develop nanocomposite material for interior aircraft application

Pioneered by AIM Altitude, Sheffield Hallam University and Composite Evolution, the thermosetting resin system has resulted in cured prepregs showing improved fire properties.

Read More