Design & Tooling

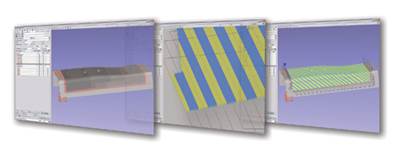

AFP/ATL design-to-manufacture: Bridging the gap

Managing production of a structure made via fiber or tape placement often requires software-aided manipulation of the subtle differences between that which is designed and that which can be manufactured.

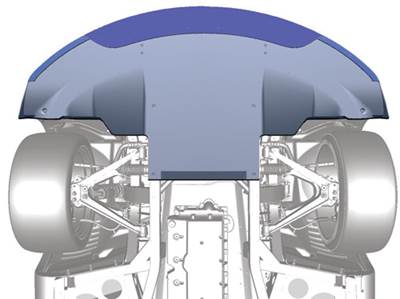

Read MoreComposite wing key to high-speed stability

First mass-produced CFRP wing helps supercar achieve downforce and lateral acceleration values superior to many GT racing cars.

Read MoreNeat resin specimen fabrication aids

To obtain quality experimental data, one must have access to quality test specimens.

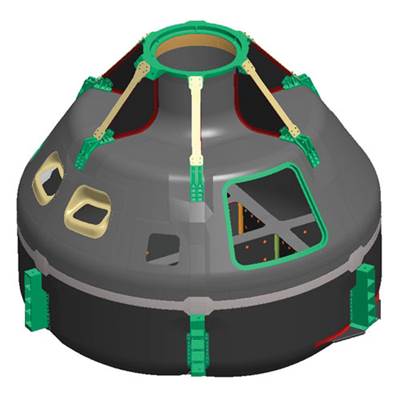

Read MoreAircraft simulation gets composites aware

Rapid software evolution enables faster, better virtual solutions to complex composite design problems.

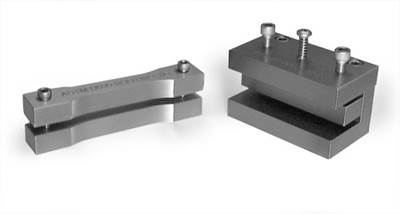

Read MoreMechanical wedge grips for tensile testing

In tensile testing, wedge grips are used on both ends of the specimen to position the specimen in the test frame.

Read MoreFinite element analysis garners performance gains for yacht component

In the ongoing quest to reduce weight in high-performance sailing yachts, no part goes unexamined or untouched.

Read MorePrototyping and manufacturing by additive fabrication

Additive fabrication (AF) technology, such as laser sintering (LS) and fused deposition modeling (FDM), encompasses a wide range of applications. The earliest was rapid prototyping to support design, concept modeling, fit/function testing, and pattern making without the need to construct expensive tooling for prototypes and test articles. Manufacturers also are using AF to produce jigs, fixtures, drill guides, and other manufacturing and assembly tools.

Read MoreInside Analysis: Simulating VARTM for better infusion

A resin flow simulation tool is helping to optimize liquid molding of aerospace parts.

Read MoreSingle-fastener, double-shear laminate bearing strength by tensile testing

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses a laminate bearing strength test using double-shear loading of a single fastener.

Read MoreCompression after impact testing

During the late 1960s and most of the 1970s, the composites industry was absorbing the impact of what was then the recent introduction of carbon fiber. The resulting composites exhibited both high strength-to-weight and high stiffness-to-weight ratios. And while it was known that composites reinforced with this new

Read More