Design & Tooling

Free-form surfacing optimizes free-style kayak

The 6-ft/1.8m-long Project 54cx kayak, made using aramid and carbon fabric-reinforced composites, weighs only 19 lb/8.6 kg.

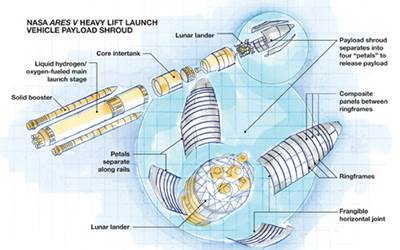

Read MoreOptimizing the Ares V payload shroud

Sizing software allows rapid analysis of candidate composite architecture for highly loaded and weight-sensitive launch vehicle component.

Read MoreSimulation simplifies fabrication of all-composite crew module

Specialized simulation software shortens development cycle on first all-composite crew module demonstrator for NASA space program.

Read MoreCompression platens and subpresses

Dr. Don Adams discusses the use of compression platens (fixed and spherical seat) and subpresses to ensure reliable test frame operation.

Read MoreDirect manufacturing of military aircraft parts

Laser sintering process shortens lead time, simplifies production of complex, high-performance parts.

Read MoreSolvent-free release a good match for wind blade molding

Wind power’s reputation as a “green” technology belies the fact that production of turbine components requires many materials and products that aren’t green.

Read MoreTeam-built bus body bests all

OEM meets tight development schedule on superlight multipart molded shell to offset propulsion system weight in fuel cell-powered transit bus.

Read MoreChallenge of engineering retrofit blades

Myriad interrelated design factors are considered in new blades for turbines originally built for high-wind regimes.

Read MoreLightweight, stable large-tool concept requires no master model

After two years of testing, partners Advanced Composites Group (ACG, Tulsa, Okla.) and GrafTech (Parma, Ohio) are commercializing the ACG GRAFOAM FPA-20 tooling system, a new concept in dimensionally stable, low-mass, high-temperature-compatible composite tooling. The system’s foundation is carbon foam.

Read MoreC-Scan inspection facility cuts cost for commercial copter

Bell Helicopter Textron’s (Ft. Worth, Texas) 429 helicopter, first revealed in 2008, is targeted to individual, corporate and emergency-services customers.

Read More