Design & Tooling

SQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

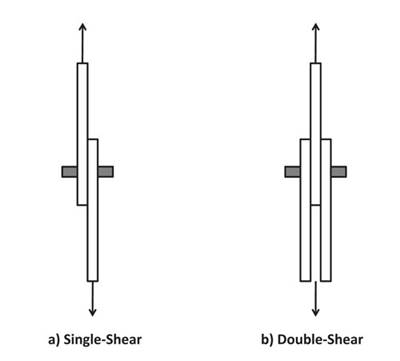

Read MoreFastener shear test methods

Dr. Donald Adams (Wyoming Test Fixtures, Salt Lake City, Utah) appraises existing methods for testing the performance of fasteners loaded in transverse shear.

Read MoreDeepsea submersible incorporates composite pressure capsule

Spencer Composites Corp. (Sacramento, Calif.) fabricates the inner carbon/epoxy composite pressure capsule for a submersible deepsea vessel the late Steve Fossett was to take to the depths of the Pacific Ocean's Mariana Trench.

Read MoreThe digital thread: Transformation to automation

Dr. Leslie Cohen traces the “digital thread” on which automation of composites fabrication processes depends.

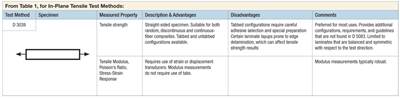

Read MoreGuide for Testing Polymer Matrix Composite Materials

Dr. Donald Adams offers insight into ASTM D 4762, a compendium of knowledge about standards relevant to testing polymer composites.

Read MoreDigital design, RTM update aircraft propeller

Second-generation type-certified propeller delivers for Cirrus Aircraft’s SR-22 at a more affordable price.

Read MoreBuilding a bigger Big Wheel

Machining specialist scales up the 1970s icon, producing plugs and tools for an exact fiberglass replica at a Disney resort.

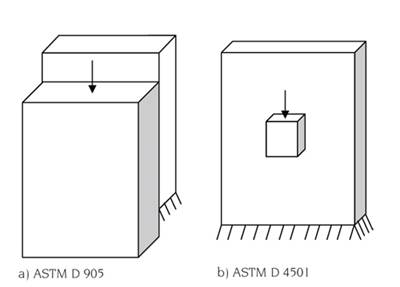

Read MoreBlock shear strength of adhesive bonds

Dr. Don Adams describes two methods (ASTM D 905 and ASTM D 4501) for loading adhesive bonds in direct shear while minimizing undesirable peel and through-thickness tensile stresses.

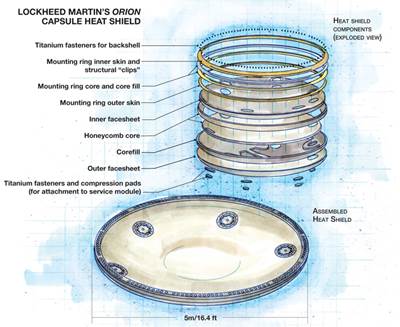

Read MoreOrion re-entry system: Composites displace metal

World’s largest heat shield updates metal design with out-of-autoclave process.

Read MoreIntegrated software: Streamlined hull & tool design

Although its reputation was solid, rigid inflatable boat (RIB) builder Planatech (Athens, Greece) recently sought ways to design new composite products and their corresponding tool sets faster, without compromising quality.

Read More