Compression Molding

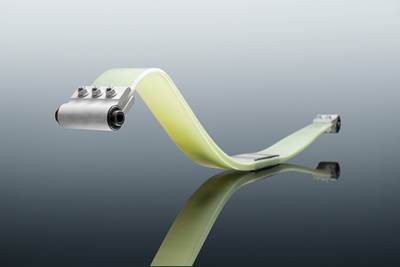

Episode 33: Ethan Escowitz, Arris Composites

CW Talks checks in with Ethan Escowitz, co-founder and CEO of Arris Composites, to learn about the Additive Molding technology his company has developed.

ListenComposites feature in Altair’s 8th Annual Enlighten Awards

Recognized jointly with the Center for Automotive Research (CAR), winners represent the world’s best initiatives to reduce vehicle weight and meet emissions targets.

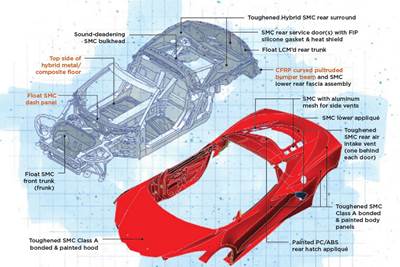

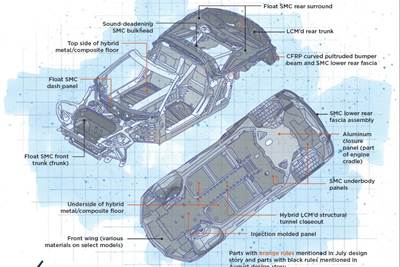

Read MoreComposites-intensive masterwork: 2020 Corvette, Part 2

Innovative composite materials trim mass, costs and noise on the high-volume mid-engine sports car.

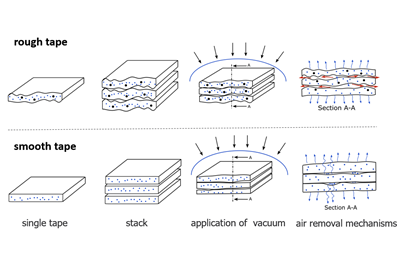

Read MoreTPRC investigates AFP in-situ consolidation alternative

The two-step process involves deposition of thermoplastic prepreg via AFP, followed by vacuum-bag-only (VBO). Research has already been completed in the qualitative stage.

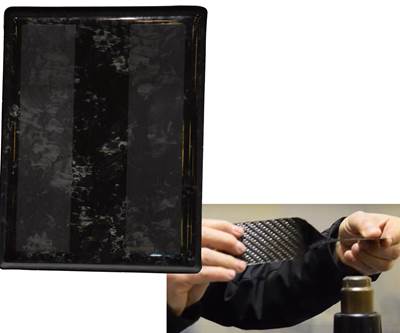

Read MoreComposites complete IYRS heavy lift quadcopter demonstrator concept

Boasting a prepreg carbon fiber airframe, the HLAP concept became a platform for a variety of composite fabrication techniques.

Read MoreLeonardo and CETMA: disrupting composites for lower cost and environmental impact

Italian OEM and tier supplier Leonardo works with CETMA R&D to develop new composite materials, machines and processes, including induction welding for in-situ consolidation of thermoplastic composites.

Read MoreThe industrialization of thermoplastic epoxy

Fast-processing composites that are strong yet tough, thermoformable, reformable, recyclable and even FST-compliant save cost in aircraft and rail equipment.

Read MoreTuplus introduces carbon fiber-reinforced polycarbonate suitcase

The highly durable suitcase, featuring front and back shells made with Covestro’s Maezio polycarbonate composite, was designed for low-cost production, high-volume production.

Read MoreSwinburne University and CSIRO's Industry 4.0 Testlab for Composite Additive Manufacturing

Australia and Germany collaborate to build Composites 4.0 production line for competitive advantage in next-gen manufacturing and workforce.

WatchComposites-intensive masterwork: 2020 Corvette, Part 1

Eighth-generation vehicle sports more composites, and features parts produced using unique materials and processes.

Read More