Compression Molding

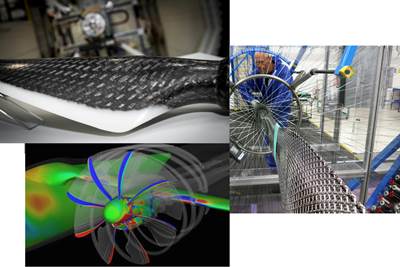

Out-of-autoclave VBO rear spar, thermoplastic ribs target Wing of Tomorrow

French Tier 1 aerospace supplier Daher develops out-of-autoclave materials and process technologies for application in next-gen structures for the Airbus Wing of Tomorrow program.

Read MoreTroubleshooting thermoforming of thermoplastic composites

Challenges with the thermoforming/stamping process and potential solutions addressing the associated parameters and complex material behaviors.

Read MoreDigiProp positions Dowty Propellers and its customers for sustainable, next-generation platforms

AMRC aids R&D program including foam thermoforming, complex braiding, thermoplastics and digital twin/thread for higher performance, lower weight with first applications in process.

Read MorePorosity, voids and bridging in prepreg autoclave and vacuum bag-only laminates

Consideration of materials, methods and systems explores ways to reduce potential surface porosity, voids, resin-rich areas, bridging and other flaws in composite laminates.

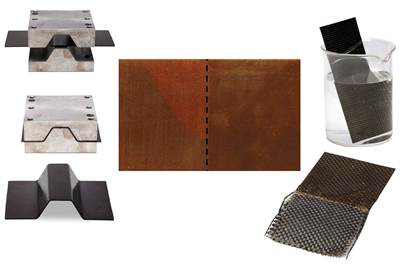

Read MoreDesigning a versatile, multi-material EV battery enclosure

Continental Structural Plastics has developed one-piece, compression-molded composite covers, an innovative fastening system and a range of material options to meet OEM needs.

Read MoreReprocessable, repairable and recyclable epoxy resins for composites

CIDETEC matures 3R resins for aerospace applications via AIRPOXY program.

WatchTeledyne CML Composites invests in thermoplastic processing capability

In conjunction with the NCC, the automated processing cell supports high-performance thermoplastic and compression-molded thermoset parts production for the commercial aerospace and defense markets.

Read MoreEasy Composites appointed as exclusive U.K. distributor of Eco-Technilin natural fiber reinforcements

Eco-Technilin natural fiber product range offers woven, nonwoven, UD and prepreg reinforcement options that are more sustainable, affordable alternatives to traditional reinforcements like glass fiber.

Read MoreStrata to manufacture compression-molded components for Pilatus PC-24

Strata to deliver composite engine mounting flaps, as well as the horizontal flap and conical stabilizer of the aircraft's tail per a seven-year deal.

Read MoreCobra International commissions prepreg compression molding production line

Production capacity delivers highly structural prepreg carbon fiber hydrofoil components with a final surface finish straight from the mold.

Read More