Compression Molding

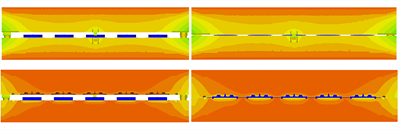

Sigma Engineering adds compression molding simulation to Sigmasoft Virtual Molding

In addition to a reworked user interface, the full process simulation software now includes the ability to view all thermal influences on the component and in the mold.

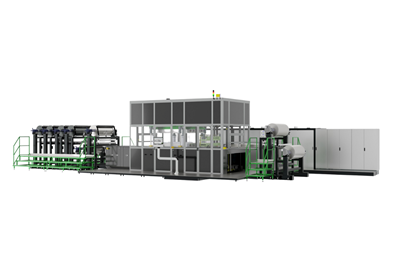

Read MoreCAMX 2022 exhibit preview: Teubert

Teubert highlights enhancements made to its continuous compression molding (CCM) system, including production scale-up, reducing required energy during production, live measurement of pressure distribution.

Read MoreGreenerd designs, engineers new 2,500-ton compression molding press

Productive, reliable molding press features an optimized mold transfer system for improved ergonomic and safety dynamics for operators.

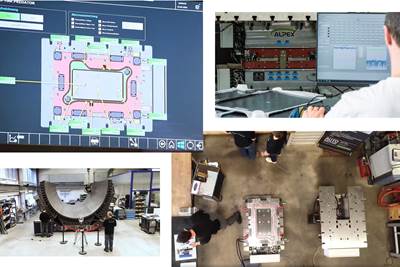

Read MoreDigitizing tools for composites production

Alpex Technologies focuses on industrialization, process and part intelligence and biocomposites in its next generation of tooling systems.

Read MoreCAMX 2022 exhibit preview: Schuler North America

Schuler’s smart control systems are said to achieve high material savings by reducing waste throughout the material cutting, distribution and forming processes.

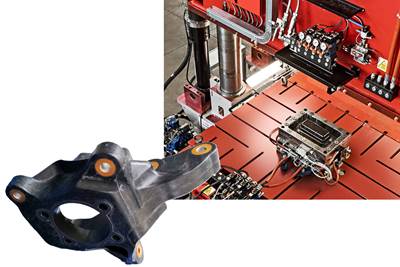

Read MoreA digital twin to validate SMC performance in suspension structures

High-fidelity, anisotropic behavior material card, integrated with process simulation, structural FEA and validated with CT and physical tests enables optimization proven in award-winning SMC suspension knuckle.

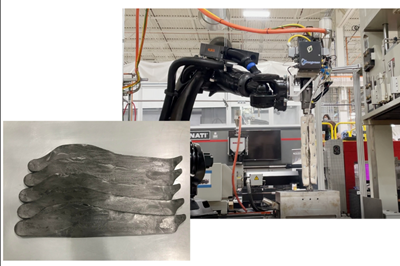

Read MoreLow-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

WatchCFRTP enables better, greener smartphones

Carbon Mobile’s “monocoque” design eliminates separate case, cover and frame, better protects electronics and simplifies disassembly.

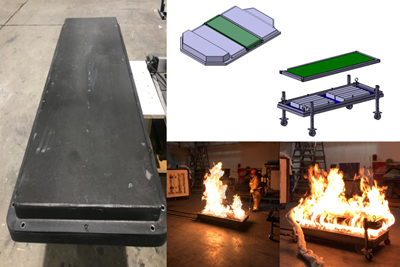

WatchPrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MoreWickert commissions composite press for ballistic plate production

Wickert reports an increasing interest in complete presses used to produce composites-intensive armor for civilian and military vehicles, ships and aircraft.

Read More