Automation

Cevotec and Composite Automation announce partnership agreement

The two companies join forces to meet the demand for automation solutions of North American composite manufacturers.

Read MoreJEC World 2018 preview: NTPT

NTPT, specialists in thin ply prepregs, preforms and parts and experts in automation technology, is showcasing a range of thin ply solutions, with particular focus on tubes, blocks and structural components.

Read MoreAirbus Helicopters' parcel delivery drone completes first flight demonstration

Skyways, Airbus’ unmanned air vehicle designed for autonomous parcel deliveries is on track to commence trial service in Singapore.

Read MoreDLR invests in automated preforming spin-off COPRO Technology GmbH

German Aerospace Center (DLR) supports reduced-cost roll-forming of composite profiles

Read MoreFiber Patch Placement at scale

SAMBA automated cells now offered in Step, Pro and Scale models, for 3D preforming dry fiber and prepreg at rates up to 15-100 kg/hr.

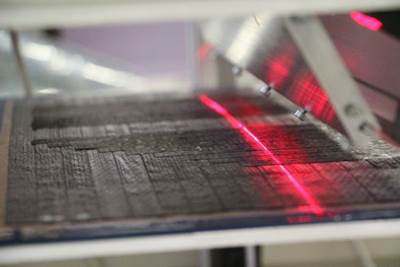

WatchImproving composites processing with automated inspection

Automated, in-situ inspection bypasses the bottleneck of manual inspection.

Read MoreConsolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

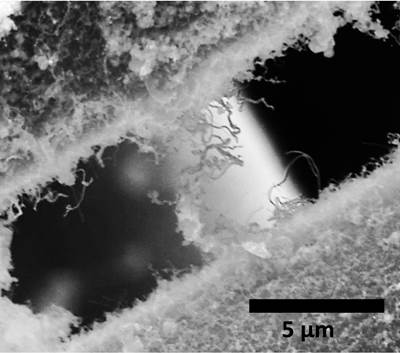

Read MoreZero-defect manufacturing of composite parts

ZAero project aims for 30-50% boost in productivity via inline AFP inspection, simulated part performance and decision support tools.

WatchCW's top 10 digital content of 2017

CW’s first list of 2018 is a simple one: The top 10 most viewed articles on the ÂÌñÏ×ÆÞ website in 2017.

Read MoreKent Pultrusion ships machine to a North American pultruder

Kent Pultrusion (Kent, Ohio), a division of Kent Automation, has successfully completed and shipped a ServoPul 1610 two stream pultrusion machine for a leading pultruder in North America producing composite wall panel structures utilizes green building technology.

Read More