Automation

Automated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

WatchAutomated Preforming, Part 2: Glide Forming

Flat layups are shaped into stringers with different cross-sections, lengths, thicknesses and curvatures using a single machine at rates up to 10 mm per second.

WatchPreforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

WatchAutomated Preforming, Part 1: Numbers and Landscape

CW’s multi-blog series on preforming begins with an overview and quick look at the numbers: 1-minute take time, 10-15 seconds per layer, 490-kg/hr and 3.5 million parts/year. Are you ready for serial CFRP production?

Read MoreProcess automation: A model response to Trumponomics and Brexit?

Offshoring can’t go on forever and a significant trend toward reshoring is probably inevitable.

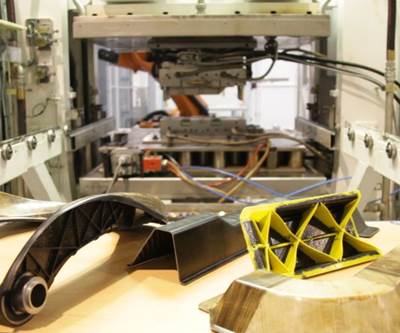

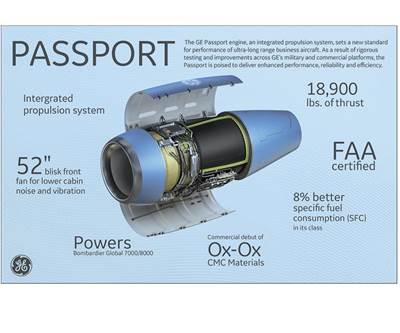

Read MoreCeramic matrix composites: Hot engine solution

Disruptive designs for composites operation in 1093°C zones.

Read MoreJEC 2017 – Aiming for Industrialization

The exhibit floor in Paris reflected composites’ move toward high-rate and high-volume production.

Watch500,000 parts per year? No problem!

BENTELER-SGL develops fully automated HP-RTM production of the weight- and space-saving composite leaf spring for Volvo’s multi-model SPA global platform.

Read MoreExclusive preview of SAMBA preforming demo

Cevotec unveils its Artist Studio software and automated SAMBA preforming cell at JEC World 2017.

WatchCW Plant Tour: Composite Technology Center, Stade, Germany

A cornerstone of Germany’s CFK Valley, CTC pushes composites forward via automation, recycling, digital thread-based manufacturing and more.

Read More