Fiber Patch Placement at scale

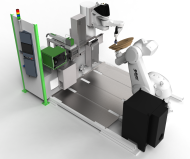

SAMBA automated cells now offered in Step, Pro and Scale models, for 3D preforming dry fiber and prepreg at rates up to 15-100 kg/hr.

I have covered Fiber Patch Placement (FPP) for some time, but Cevotec has recently announced multiple developments that expand its capabilities in composites:

- Demonstration and market launch of SAMBA Pro at JEC 2017

- Exhibition of aircraft window frames at 2017 Paris Air Show

- Introduction of SAMBA Scale for high-volume preforming

- Launch of dry fiber cevoTape for AFP/ATL

- Demonstration of FPP using prepreg tape (e.g., HexPly M21 from Hexcel)

- Offering of cevoPads for localized reinforcement (e.g., holes, attachment points”)

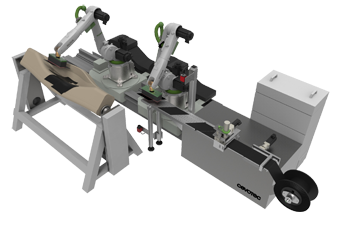

Automated production line using multiple Cevotec SAMBA Scale preforming cells (left) for high-volume composites preforming and cevoTape dry fiber and prepreg unidirectional tape (right) for FPP, AFP and ATL processes. SOURCE: Cevotec.

SAMBA launch and Window Frames

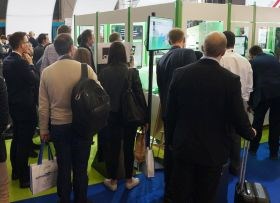

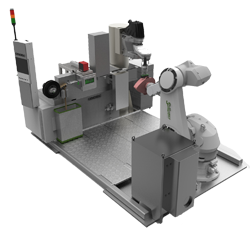

Cevotec attracted quite a crowd to its live demonstration of the automated SAMBA FPP preforming cell at JEC World 2017 (Mar 14-16, Paris, France). “After several sneak previews with our system in a VR [virtual reality] environment, people for the first time could watch SAMBA integrally creating a complex fiber preform: an aerospace gearbox with concave and convex surfaces, including 90° angles and small radii”, said Felix Michl, Cevotec CTO. Highlights were the speed of one patch per second, the accuracy of the layup and the advantages of the built-in CAD-CAM software ARTIST STUDIO for digital product development.

Cevotec’s demo of its SAMBA Pro automated preforming cell at JEC 2017 drew crowds and interest. ARTIST STUDIO, its built-in CAD-CAM software, augments the cell by enabling very fast digital product development and iteration. SOURCE: Cevotec.

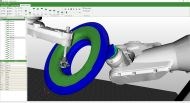

Three months later, Cevotec showed the world’s first FPP aircraft window frame at the Paris Air Show. Cevotec managing director Thorsten Groene describes the part as biaxially curved, requiring a fiber architecture with constant radial and circumferential orientation. “There are various ways of producing this part”, explains CTO Michl. “But most require multiple bindered carbon deposition and preforming steps, resulting in an expensive and slow process which is not optimized for efficiency.”

Using SAMBA, Cevotec can eliminate several production steps and manual processes, speeding the production cycle time and cutting cost by up to 50%.

“The resulting composite part also exceeds the strength and load-bearing capacity of metal at a fraction of the weight while enabling geometries that are not possible or are too labor- and cost-intensive with traditional composite technologies,” says Groene.

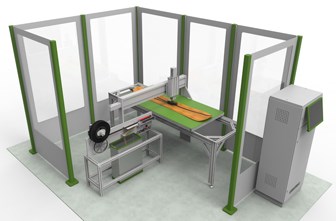

Cevotec displayed world’s first FPP aircraft window frames at the 2017 Paris Air Show and has now developed SAMBA automated preforming cells that can process prepreg.

SOURCE: Cevotec.

FPP at Scale

The SAMBA automated preforming systems is now available at three scales to meet a wide range of production settings and requirements. The SAMBA Pro is targeted for flexible, high-volume batch production of composite parts, while SAMBA Scale enables high-volume production with material placement up to 15 kg/hr. Combining multiple SAMBA cells enables a throughput up to 100 kg/hr, even for highly complex 3D-preforms. Multiple patch robots also enable hybrid components, for example using primarily glass fiber with carbon tape placed only where needed for additional strength and/or stiffness.

Cevotec now can process this type of preform with prepreg.

SAMBA Step is tailored for small-scale production, prototyping and R&D, with a corresponding lower price, and is available as a 3D or 2.5D unit.

“Benefits of Virtual Product Development”

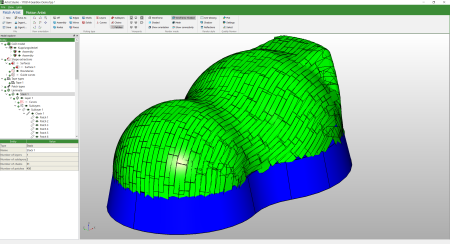

Cevotec has also published a detailing the benefits and possibilities of virtual product development for lightweight composite parts based on extensions of its SAMBA system and ARTIST STUDIO CAD-CAM software. The software is being equipped with an interface to standard FEM software, enabling the calculation and simulation of mechanical properties of patch laminates.

|

|

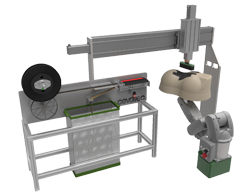

cevoPads provide localized reinforcement around holes and attachment points, while cevoTape offers high-quality preform material input for SAMBA cells as well as AFP and ATL. SOURCE: Cevotec.

cevoTape and cevoPads

As the right fiber is crucial for the quality of a composite part, Cevotec has launched its own high-quality , which is also well-suited for other fiber placement processes like AFP and ATL. Meanwhile, cevoPads are available in prepreg or binder-fixed, dry fiber — both stable and easy to handle in further processing. Different thicknesses are available and individually-tailored reinforcement patterns are possible.

Cevotec will be exhibiting at JEC World 2018 (March 6-8, Paris, France) in Hall 5A, P66.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More