Automation

CompositeTechs to introduce Airborne portfolio to North American market

Digital composites automation equipment and services will be made available to accelerate composites adoption across a wider range of end markets.

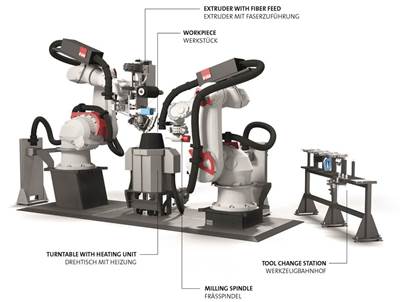

Read MoreFill ACCUBOT combines extrusion with continuous fiber additive capabilities

The system’s additive capability, augmented by subtraction via integrated robotic milling creates the potential for the production of cost-effective, high-performance and multifunctional composite components.

Read MoreWEAV3D awarded NSF funding to further develop next-generation composite forming machine

Two-year award will fund design, fabrication and testing of composite machine, which addresses high part cost and low production throughput in composite manufacturing.

Read MoreEpisode 38: Alan Hiken, Kane Robotics

Alan Hiken, COO of Kane Robotics, talks about historic, current and future composites use in aircraft fuselage structures and the role of automation in next-gen manufacturing environments.

ListenNCC unveils AFP/ATL dual system for large, complex structures

The hybrid cell, created in partnership with Electroimpact, can be used individually or together for automated composite manufacturing at a medium- to large-scale level.

WatchWickert multifunctional gripper improves automated workpiece handling

Set-up free gripper handles multilayer-stacked components uses cameras, image processing and an integrated position sensor system for uninterrupted handling, automation and machining operations.

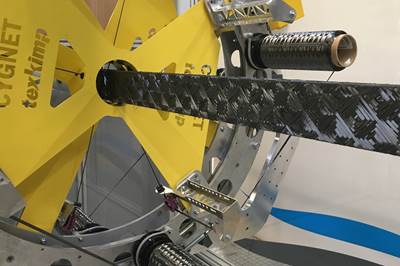

WatchNWCC, Cygnet Texkimp collaboration to advance data on winding capability for composite parts

Research project to demonstrate damage tolerance and impact resistance of composite parts manufactured with new multi-axis winder and 3D winding technologies for further development and commercialization.

Read MoreHexagon, Authentise end-to-end software platform streamlines AM workflow

Solution integrates shop floor data with data intelligence to orchestrate consistent quality through concept to part for AM industrialization.

Read MoreAxillium to support, manage U.K.’s ASCEND program

Innovation management partner Axillium explains its role in development of the Aerospace and Automotive Supply Chain Enabled Development (ASCEND) program launched in the U.K. in March 2021.

Read MoreIncreasing demand for composite driveshafts leads to automated production

California-based fabricator ACPT Inc. worked with machine suppliers to build an innovative semi-automated production line featuring an automated filament winder.

Read More