CompositeTechs to introduce Airborne portfolio to North American market

Digital composites automation equipment and services will be made available to accelerate composites adoption across a wider range of end markets.

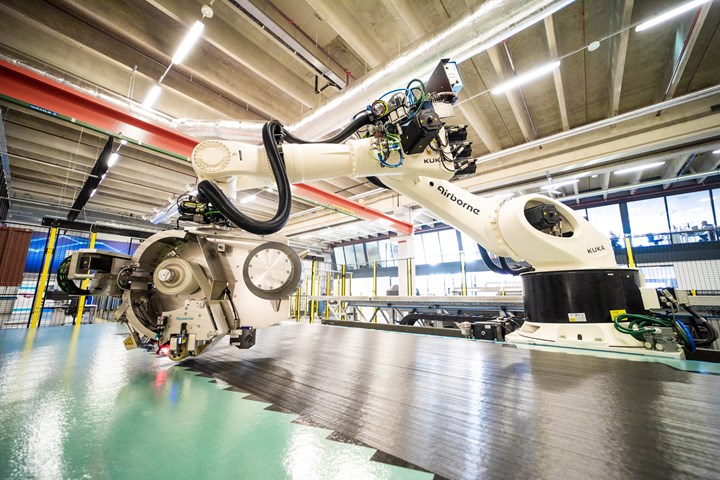

Photo Credit: Airborne.

Digital automation platforms specialist Airborne (The Hague, Netherlands) has reached an agreement with CompositeTechs LLC (Amesbury, Mass., U.S.), a composite materials and services company. Throught this cooperation, CompositeTechs will introduce select products from Airborne’s equipment and services portfolio to the North America market.

Airborne manufactures efficient and fully digital composites automation equipment. The company says it applies its extensive composite manufacturing know-how to the design of its systems and software to deliver reliable, fast and high-quality automated processes. Further, Airborne offers a portfolio of off-the-shelf standard solutions and can reports that it can also develop a customized, dedicated industrial manufacturing system in which third-party equipment is integrated into one fully automated system.

“We are excited about this relationship with Airborne to bring their innovative products to the North American marketplace,” says Mike Favaloro, president of CompositeTechs. “Airborne’s legacy in advanced composites manufacturing makes them experts in developing and delivering automated solutions that will enable our customers to achieve high production rates with radically low conversion costs. As onshoring and automation accelerates in this new economy, we are honored to be working with the company that can provide the best value for our customers.”

According to Joe Summers, commercial director of Airborne, a lot of current technologies are still complex to users. “We see it as our job to deliver easy-to-use, plug-and-play innovative solutions. This accelerates the composites adoption across more markets,” Summers says. “CompositeTechs has a proven track record of providing high-quality technical and sustainable solutions across multiple segments of the composites industry. Together, we aim to empower the automation of production lines and higher production volumes against reduced production costs for the right members within the composites community.”

Related Content

-

Laser cleaning in composites manufacturing

Laser cleaning technologies for cleaning production molds for composites offer alternatives to harsher, less-friendly methods with features like automation and higher power cleaning.

-

Flyber launches U.K. composites manufacturing site for advanced mobility applications

The startup’s design automation and composite material layup and curing technologies target lightweighting for aerospace, UAVs, eVTOL and high-performance mobility platforms.

-

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.