Search Results

Showing 111 – 120 of 702 results

Michigan-based Ground Test Solutions (GTS) shares the design and manufacturing processes involved in building composite nacelle components used in testing jet and helicopter engines.

The RedMini controller can be connected to any msquare silicone heating blanket for simple and homogeneous composite heating and repair.

CAMX 2023: Kingspan Insulation is highlighting its EPS composite and ISO-CF structural foam core, low-temperature pipe and mechanical insulation and sheet insulation solutions.

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Starting with the sporting goods and bicycle market, French startup 3DiTex targets its continuous preforming system for thermoformable, thermoplastic composite tubes in complex geometries.

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Pioneering technocenter advances RTM, thermoplastic composites, additive manufacturing, microwire, novel lighter weight LSP and more.

Tension leaf springs with progressive spring rates meet the demanding needs of truck suspensions.

Four types of carbon fiber 3D noodle, or gusset filler dry preforms, are offered with pre-defined radii. They are also well suited for aerospace applications.

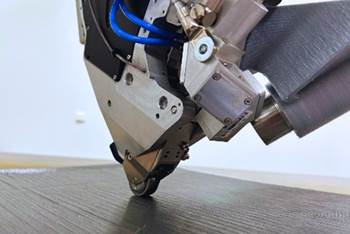

This compact cell brings together 3D printing, AFP and milling aided by a comprehensive software program, further simplifying the manufacture of complex thermoplastic composite aerostructures in the future.