Suprem launches continuous fiber-reinforced thermoplastic brand tailored to AM

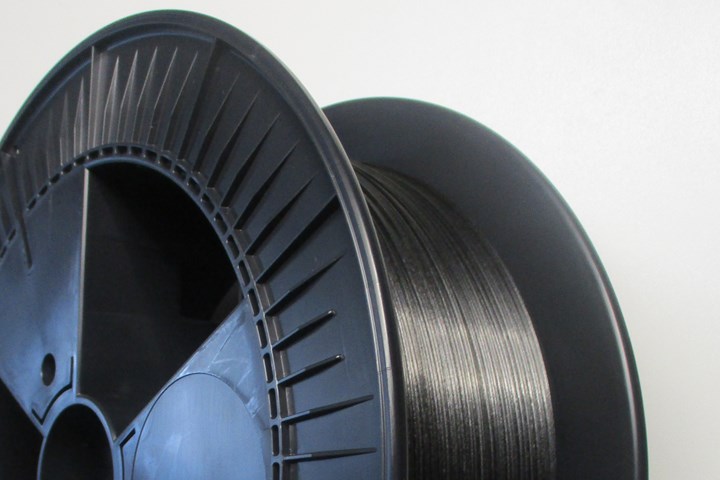

Filaprem materials feature high quality, exceptional fiber/matrix distribution and low porosity.

Photo Credit: Suprem SA

Suprem SA (Yverdon-les-Bains, Switzerland), offering 35 years of experience in developing and manufacturing products for additive manufacturing (AM), is launching a new brand, Filaprem, for continuous fiber-reinforced thermoplastics for 3D printing. Filaprem materials are said to be tailored to replace steel, titanium or aluminum alloys with composites, and to locally strengthen plastics for lighter, stronger parts.

Suprem points to Filaprem’s high quality, exceptional fiber/matrix distribution and low porosity, all of which enable printed parts with low downtime and minimal scrap. High mechanical performance and enhanced temperature resistance are also features mentioned by the company. Further, Dr. Anatole Gilliot, CEO, says the Filaprem brand opens new opportunities for the design of small, complex parts, as well as remote, automated manufacturing.

Suprem’s materials can be applied in various applications from marine to space end markets.

Related Content

-

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.