Veelo Technologies debulking system enables OOA composite aircraft rotor blade processing

In-situ heating blankets offer a highly drapable solution for uniform heating coverage over complex surface areas.

All photo credit: Veelo Technologies

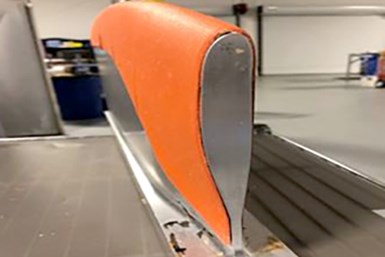

Veelo Technologies (Cincinnati, Ohio, U.S.) announced on Feb. 23 that its patented heating blankets, the VeeloHEAT Caul, can be applied to composite aircraft rotor blades. Tailored for use in composite debulking and bonding applications, the system enables in-situ hot debulk, eliminating the need to transport long and bulky rotor blades to an oven. This in turn improves build and repair rates while also reducing scrap.

According to the company VeeloHEAT Caul is designed for flexibility and pliability, enabling a highly drapable solution that provides uniform heating coverage across the large and geometrically complex surface areas found on rotor blades. The heating blankets are also said to easily accommodate custom shapes and large tools with minimal or few bridging issues. They are durable and damage resistant and are offered in an optional FKM-based heater system for high performance and material compatibility.

Use of VeeloHEAT Caul on aircraft rotor blade.

“Our VeeloHEAT solution is currently used by the aerospace composites industry to bond and repair multi-million-dollar composite aerostructures,” says Mr. Joe Sprengard, Jr, president and CEO at Veelo. “We are helping them accelerate adhesive cure, perform faster composite repairs and improve the debulk processes. For rotor blades specifically, the net-shape draping that occurs with our blankets can help a manufacturer or repair facility realize substantial savings and improvement in build and repair rates. We provide an effective alternative to taking these blades to the oven.”

Related Content

-

AM method enables tool-free, energy-efficient thermoset composites production

University researchers highlight how the combination of a thermally curable resin system with photothermal curing eliminates the post-curing steps involved in discontinuous, continuous fiber parts fabrication.

-

Clean Sky 2 outer wing box demonstrator validates OOA LRI, shimless assembly and SHM

Full-scale wing box project achieves TRL 5 with 2% weight reduction and 4% reduction in recurring production costs through improved manufacturing efficiency and assembly processes.

-

Flyber launches U.K. composites manufacturing site for advanced mobility applications

The startup’s design automation and composite material layup and curing technologies target lightweighting for aerospace, UAVs, eVTOL and high-performance mobility platforms.