Orion's final assembly begins

Lockheed Martin have completed construction on the spacecraft capsule structure and have shipped the capsule to Florida for final assembly.

Lockheed Martin (Denver, CO, US) announced Aug. 28 that technicians have completed construction on the capsule structure, or pressure vessel, for NASA's Orion Exploration Mission-2 (EM-2) spacecraft, and have successfully shipped the capsule to the Kennedy Space Center in Florida for final assembly into a full spacecraft.

The capsule structure was welded together over the last seven months by Lockheed Martin technicians and engineers at the NASA Michoud Assembly Facility near New Orleans, LA, US.

"It's great to see the EM-2 capsule arrive just as we are completing the final assembly of the EM-1 crew module," says Mike Hawes, Lockheed Martin vice president and program manager for Orion. "We've learned a lot building the previous pressure vessels and spacecraft and the EM-2 spacecraft will be the most capable, cost-effective and efficient one we've built."

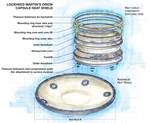

Orion's pressure vessel is made from seven large, machined aluminum alloy pieces that are welded together to produce a strong, light-weight, air-tight capsule. As part of the final assembly, the capsule will be joined with a composite heat shield that will shield Orion from the extreme heat it will experience as it returns to Earth.

"We're all taking extra care with this build and assembly, knowing that this spaceship is going to take astronauts back to the Moon for the first time in four decades," says Matt Wallo, senior manager of Lockheed Martin Orion Production at Michoud. "It's amazing to think that, one day soon, the crew will watch the sun rise over the lunar horizon through the windows of this pressure vessel. We're all humbled and proud to be doing our part for the future of exploration."

Related Content

-

Near-zero erosion ultra-high temperature CMC

K3RX commercializes UHTCMC for a wide range of markets, demonstrating performance in prototypes, assemblies and advancing manufacturing to reduce cost.

-

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

-

On the radar: Reusable launch vehicles, hypersonics make space more accessible

CFRP has become key to targeting efforts in reusing components like rocket stages, as well as the development of reusable hypersonic testbeds and spaceplanes, for increasing space commercialization.