Compoxi installation widens AFP-XS technology application domain

Compoxi aims to characterize and qualify the AFP-XS and new materials for adoption in the growing Space and New Space markets.

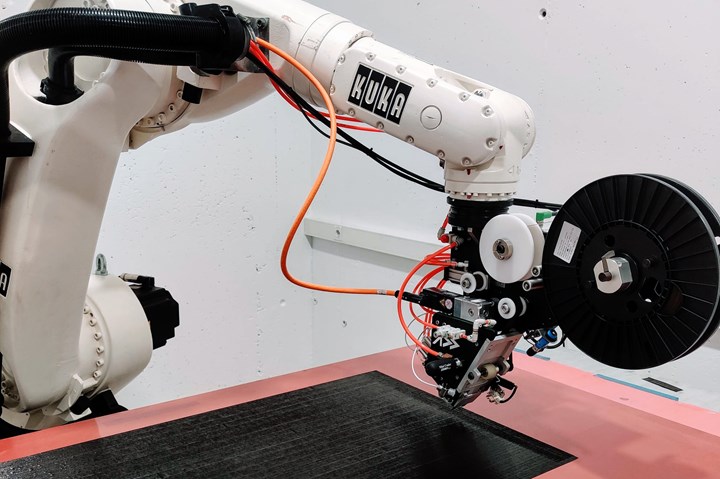

Photo Credit: Compoxi

(Girona, Spain) has installed an automated fiber placement (AFP) solution from Addcomposites (Espoo, Finland). The compact AFP-XS technology enables layup with high placement accuracy for space applications with aligned continuous fibers and very little manual labor.

Compoxi’s manufacturing facility, located in Girona, Spain, is suited for the manufacturing of advanced composites structures with the latest state-of-the-art equipment. Compoxi, with its know-how in materials and processes which were acquired through more than 10 years of experience, says it strives to provide the best solution for space and aeronautic markets.

With the latest AFP-XS installation, Compoxi aims to:

- Characterize and qualify AFP-XS technology for space applications, as well as explore new, sustainable materials for this market.

- Increase Compoxi’s know-how to offer a broader range of services and portfolios to its customers.

- Offer new services to growing New Space economy targeting constellation and medium-to-high volume productions.

“Higher placement accuracy, especially with qualified materials for space applications, will widen the application domain of the AFP-XS technology,” says Addcomposites CEO, Pravin Luthada. “We are fully committed to supporting process development work at Compoxi that will enable faster adoption of such accessible technologies in the space applications.”

“Our goal is to qualify the process and materials that meets the criteria set forth by main stakeholders of Space and New Space markets that Compoxi is serving,” adds Compoxi CEO, Marc Gascons. “We believe this would help reduce the major barriers for the adoption of compact AFP solutions for producing high-quality composite parts at adequate rate and cost for each particular space application.”

Related Content

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

Carbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

-

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.