Addcomposites Oy

Betonimiehenkuja 5C

Espoo, Uusimaa 02150 FI

358 50330 5201

info@addcomposites.com

About Addcomposites Oy

Addcomposites provides the plug-n-play solution for advanced composites manufacturing on an as-needed basis. Universities, research institutes, and small manufacturers can rent the system for teaching, industry projects, and small series production, instead of buying a multi-million euro system.

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

Addcomposites Oy Supplies the Following Products

- 3D Printing / Additive Manufacturing

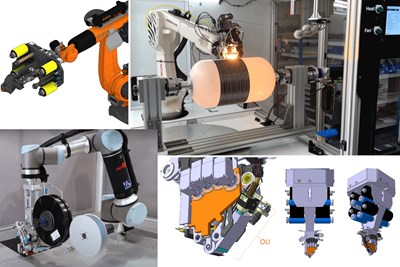

- Automated Fiber Placement Systems

- Automated Tape Laying Systems

- CAD/CAM Software

- Composites Controls & Software

- Composites Process Development

- Continuous Laminating Machines

- Filament Winding Machines & Controls

- Modeling/Simulation/Virtual Testing Software

- Pressure Vessels

- Winders/Rewinders

Trade Names Offered by Addcomposites Oy

Editorial, News, and Products

-

Addcomposites releases free professional composites design software suite

Browser-based tools eliminate $320,000 annual licensing barriers, making advanced composite engineering accessible to 50,000-plus engineers and educational institutions worldwide.

-

ÉireComposites joins TOSCA project tackling aerocomposite hurdles

Epoxy vitrimer resins, inspection and health monitoring, as well as innovative and digital processing techniques are objectives for this eight-partner EU project.

-

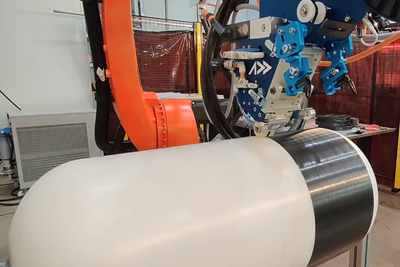

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

Addcomposites announces AFP-XS global install base milestone

More than 50 of the production-ready AFP solution for small- to medium-scale composite part manufacturing have been installed and is rapidly growing thanks to its affordability and versatility.

-

Plug-n-play AFP/ATL equipment, adaptive mold and integration solutions eases adoption

CAMX 2024: Addcomp distributes its AFP-XS systems and now adaptive molds, works with customers to design and install custom systems and develops its capabilities with new partnerships.

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

Addcomposites introduces structural continuous fiber 3D printing

Large-format 3D printing head is equipped to align and precisely print continuous fiber and chopped fiber formats without compromising on resulting part strength, weight or quality.

-

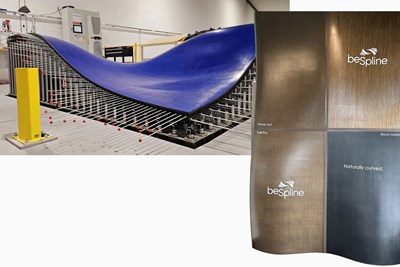

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

Addcomposites highlights novel composites manufacturing developments

AFP-XS and AddPath updates, new AFP and continuous AM systems, upcoming webinars and blog content are available to interested industry members.

-

IFW’s AFP installation enhances thermoplastic structure production

Commissioned AddComposites AFP manufacturing cells with humm3 flashlamps are located at IFW’s Stade and Garbsen facilities to expand R&D services.

-

CAELESTIS R&D project explores predictive design, manufacturing for aerospace

Over 42 months, 11 partners will work together to develop an end-to-end digital thread to effectively enable dataflow across the entire aircraft value chain, accelerating the optimization of disruptive aircraft and engine configurations.

-

CAMX 2022 exhibit preview: Addcomposites, IND Group

The co-exhibition shows customers a more complete visual of the value chains that can be implemented in the composites industry via Addcomposites’ AFP system solutions and IND Group’s cobot platforms.

-

Addcomposites path-planning, simulation and defect detection platform for AFP

Purpose-built OLP software platform, AddPath, now supports multiple AFP tools, enabling end users to use their own existing hardware.

-

AFP-XS platform demonstrates rectangular tube manufacture

Addcomposites collaborated with MBDA and Compositadour to produce lightweight, stiff and weatherproof components that are electrically insulating, chemically resistant and dimensionally stable.

-

Addcomposites brings multi-tow AFP system to the composites market

The automated system offered by Addcomposites is adaptable to complex shapes and enables multi-format and multi-material type preforming.

-

Addcomposites AFPnext program grows digital automation capabilities for composites manufacturing

AFPnext aims to increase access to advanced composites manufacturing by eliminating key risks to manufacturers.

-

Addcomposites adds tape winding to Finland facility for pilot trials

The new capability, which enhances the available level of design freedom, was added to encourage manufacturers to develop new innovations using tape winding.

-

Compoxi installation widens AFP-XS technology application domain

Compoxi aims to characterize and qualify the AFP-XS and new materials for adoption in the growing Space and New Space markets.

-

Quebec composites development center installs AFP capability

Robotic cell by Effman, Fanuc and Addcomposites enables automation of complex composite layups with tailored fiber orientation for small and medium enterprises (SMEs).

-

UT Austin installs Addcomposites AFP-XS with laser for in-situ consolidation of thermoplastic composites

Modular, compact and versatile AFP system to help University of Texas explore thermoplastic composites technologies.

-

The democratization of composites is reconfiguring supply chains

New robotic and digital technologies are enabling advanced in-house capabilities for small companies and innovative suppliers willing to embrace the move toward more affordable, sustainable composites.

-

Effman installs AFP-XS as part of project to enable AFP for SMEs

uCOMP project with Addcomposites and Quebec partners demonstrates new woven tape and high-permeability preforms for resin infusion in <2 minutes.

-

Addcomposites installs AFP-XS at Compositadour and integrates humm3 flash lamp

French technology platform expands access to composites beyond aerospace, while humm3 offers cost-effective dry fiber and thermoplastic tape placement in addition to CF/epoxy prepregs.

-

Addcomposites and Effman partner to provide AFP cells for SMEs

Aim is affordable, enclosed composites manufacturing cells for many different processes (AFP, grinding, buffing, sanding, drilling) in North American market.

-

Remotely installing an AFP system amid COVID-19 travel restrictions

Addcomposites has completed remote installation of AFP-XS for Regional Institute of Advanced Materials (IRMA) in France.

-

Plug-and-produce AFP system installed in one day and debuts at composites automation center

Addcomposites completes installations of its AFP-XS toolhead at KUKA Finland and SAM|XL in Netherlands.

-

Addcomposites' virtual demo on how to make an AFP composite laminate

Readers are walked through how to program and operate the AFP-XS plug and play system.

-

Increasing access to AFP

Addcomposites is democratizing composites manufacturing by leasing a low-cost toolhead that turns any robot into an automated fiber placement machine.

-

Addcomposites introduces plug & play AFP/ATL for cost-effective composites manufacturing

New AFP-XS turns any robotic arm into an automated composites manufacturing system.