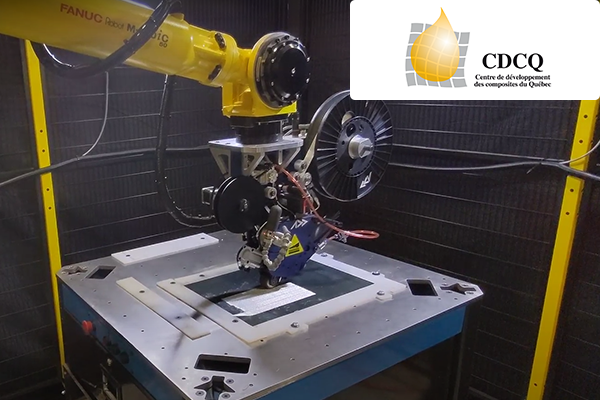

Quebec composites development center installs AFP capability

Robotic cell by Effman, Fanuc and Addcomposites enables automation of complex composite layups with tailored fiber orientation for small and medium enterprises (SMEs).

Photo Credit: CDCQ

The Centre de développement des composites du Québec () at Cégep Saint-Jérôme (Québec, Canada) has installed an automated fiber placement (AFP) robotic cell developed by automation specialist Effman (Sherbrooke, Quebec, Canada) with the help of the FANUC robot and AFP head fromAddcomposites (Espoo, Finland). The AFP technology enables layup of complex parts or preforms to be fabricated with aligned continuous fibers and very little manual labor. This new technology is intended to be accessible to small and medium enterprises (SMEs).

CDCQ offers manufacturing companies a wide range of services tailored to their needs in the composite materials sector. Based on the growing use of advanced composites in non-aerospace applications, CDCQ decided to invest in the technological know-how to support local companies.

CDCQ has issued a local call where partners can utilize the newly acquired capability to resolve their challenges, such as:

- Develop materials (tapes) with resins and reinforcements adapted to the non-aerospace needs including land transport, sports equipment and industrial applications;

- Hybrid reinforcements and increased areal weight (grams/square meter, GSM) tape reinforcements, as well as modified resins for fire and/or impact resistance;

- Make dry preforms for infusion molding or resin transfer molding (RTM) processes;

- In collaboration with other centers, work on the optimization of deposition head mechanics and robot trajectories as a function of the material characteristics and processing parameters.

Related Content

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

-

McLaren develops aerospace-inspired ART method for volume composite super car engineering

Automated rapid tape (ART) technique, already deployed at the MCTC and to be used for future McLaren models, is capable of producing lighter, stiffer and stronger carbon fiber structures with less waste.