Clean Sky 2’s PASSARO project targets one-shot OOA composite cockpit

Synergies with MOSHO project for NDT, repair and also developing cobots for 70% cut in cycle time.

The PASSARO (caPAbilities for innovative Structural and functional testing of AeROstructures) project aims to develop new multifunctional materials — integrating noise insulation and high energy impact resistance — and inspection solutions for new composite cockpit manufactured in one shot and complemented with out of autoclave (OOA) technologies such as thermoplastic composite in-situ consolidation and liquid resin infusion. This composite cockpit was developed by Airbus Defence and Space (Madrid, Spain) during Clean Sky 1, based on the C295 aircraft. The project is also targeting the automatization of manufacturing processes as well as new testing approaches based on Industry 4.0 concepts and developing ergonomic advanced concepts promoting the pilot comfort and improved human machine interface.

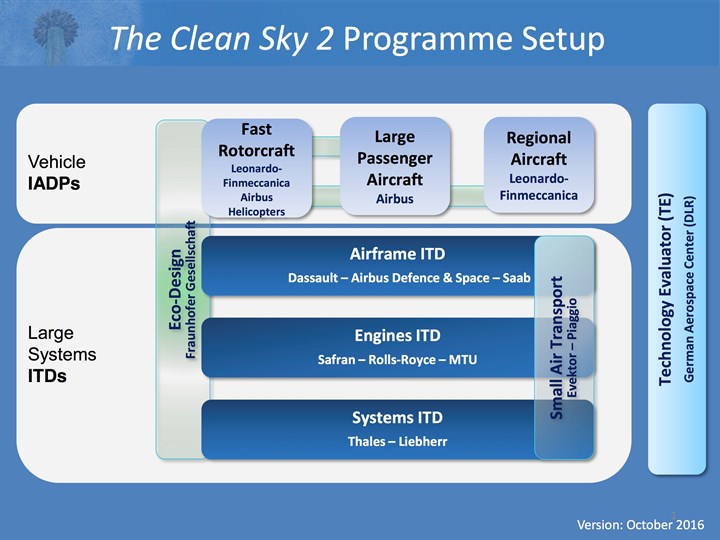

The , part of Clean Sky 2’s platform, started in July 2016 with a total duration of 48 months. It comprises eleven partners from Portugal and Spain working in close collaboration with Airbus Defence and Space.

Synergies with Portugal regional MOSHO project

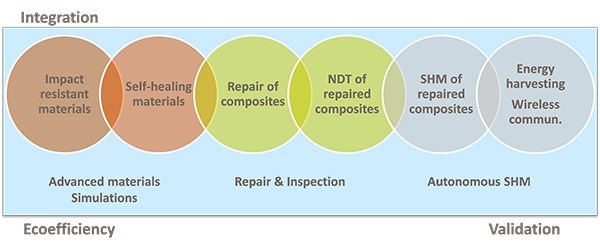

Many Clean Sky 2 (CS2) projects share synergies with regional EU member initiatives (e.g., CORAC in France). The PASSARO project has promoted complementary activities with Portuguese national R&D initiatives. The MOSHO project (Advanced solutions for impact materials, repair of composite aero-structures and their monitoring) complements PASSARO activities in which some of the partners are involved and is supported by ADS (Airbus Defence and Space) as the Clean Sky 2 coordinator for the Airframe ITD. The project will develop and integrate advanced solutions for the repair of composite aerostructures.

Figure 3: MOSHO project technical scope SOURCE:

PASSARO collaborative robots cut hand layup cycle time by up to 70%

As part of the PASSARO project’s objectives to research and develop how to employ collaborative robots in composites manufacturing, the OPTIMAL project developed a practical and cost-effective automated solution to replace traditional hand lay-up, using qualified materials.

Traditionally, the manufacture of composite components using prepreg is essentially a handmade activity, but steps are being taken towards automation. During the past decade, several automated lay-up solutions have emerged for relatively simple geometry parts. These solutions are often quite expensive, and commonly demand factories to be designed from scratch for their installation. They typically require special environments in the form of isolated cells with dedicated safety systems. As an alternative, collaborative robots (cobots) could be integrated into the existing manufacturing workflows to automate some tasks and improve productivity without drastically changing the surrounding environment.

Industrial robots are fast, strong and have exceptional accuracy and repeatability, but they are developed aiming only at optimization of the final result. In comparison, cobots are slower, less accurate and handle smaller payloads, but have what is needed to automate simple tasks, especially alongside with humans, at considerably less cost. Cobots have load sensors which detect the smallest impacts and stop safely.

OPTIMAL´s objective when developing cobot technologies is to improve its own capacity, and that of other companies, to offer more repeatable, higher-quality products in large quantities and at lower prices.

Within the PASSARO project’s Work Package 10, three main steps were developed using collaborative robots:

- Ply pick-up and sorting, directly from the automated ply cutter;

- Ply peeling using a dedicated cell;

- Ply positioning and stacking in a tool.

To implement these activities, a cell was developed which receives prepreg plies from the ply cutter and automatically peels and stacks them onto a mold.

Collaborative robots used for composite manufacturing in the PASSARO project. SOURCE:

Positioning and stacking tasks are completed by the robot arm using special suctions cups for prepreg handling. The peeler is a more complex machine, utilizing compressed air to peel the prepreg, which is protected by two coatings — typically one plastic and one paper, or simply by two plastics. The peeling concept is based on the fact that different materials tend to vibrate at different frequencies when the same stimulus is applied. The different vibration frequencies produce air pockets between the prepreg and the covering layers. The plate resonator adjusts the vibration amplitude for different materials. This prototype could achieve peeling rates with near 100% success for specific materials and a stacking accuracy of ± 0.5 mm, in each of the two degrees of freedom in plane of the mold, and ± 0.1º in rotation.

The modular approach adopted for this system makes it independent of ply dimensions. The width is covered by adding more parallel peeling modules and the length by adjusting the peeler opening range. This technology, when compared with a human operator, offers a clear improvement in process accuracy, repeatability and especially cycle time, with reductions up to 70%.

Authors: António Reis, Nicole Cruz, Marco Neves (OPTIMAL) and Rúben Buelga Sanchez (ADS). For more information, contact:

INEGI

Campus da FEUP

Rua Dr. Roberto Frias, 400

4200-465, Porto, Portugal

Tel: (+351) 229 578 710

Email: passaro@inegi.up.pt

Related Content

Engel supports composites upcycling research at TH Rosenheim

Engel Group has provided the Rosenheim University of Applied Sciences with a vertical injection molding machine for further R&D into the processing of thermoplastic, recyclable composites and the application of natural fibers.

Read MoreSiemens software chosen for JetZero BWB aircraft concept, launches Xcelerator updates

Aviation startup will use the Xcelerator platform to achieve its aircraft vision. Other Siemens collaborations deliver software additions to deliver, democratize industrial AI for small companies, startups.

Read MorePlant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More