Articles

Bladder and caul solutions for trapped & complex composites fabrication

Smart Tooling reviews the function and application of its shape memory polymer tooling bladder and caul solutions for the efficient and cost-effective manufacture of trapped and complex geometry composite parts and structures.

Watch3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

Read MoreDesigning the ultimate stand-up fishing kayak

Apex Watercraft’s new Tyr carbon fiber/epoxy prototype reimagines the typical kayak design and promises the highest performance possible.

Read MoreCorrection: First CFRP fuselage in Mexico was Stela-M1 trainer

Aeromarmi built an all-composite fuselage before RHEM Composites.

Read MoreResearchers introduce capillary-driven method for continuous fiber 3D printing

The LITA 3D printing system from the University of Delaware shows potential for in situ cure for high-performance carbon fiber composite parts.

Read MoreComposite Bonding & Repair Benefits and Solutions

Film and paste adhesives, wet peel-ply and potting compounds enable the aviation industry to utilize advanced materials that contribute to lightweighting, more efficient designs, and improved sustainability.

WatchUsing nondestructive testing to inspect, repair carbon fiber bicycles

An Oregon-based bicycle inspection and repair shop uses an Olympus ultrasonic thickness gage to evaluate and fix structural damage.

Read MoreHome building with composites

There’s a house being built next door. It could be using more composites.

Read MoreDemonstrating recyclable, bio-based autocomposites

The ECOXY research consortium recently developed a demonstrator automotive part constructed from recyclable flax fiber and a specialized bio-based epoxy.

Read MoreComposite sandwich panels enable flexibility in medical table design

Polyurethane foam core provides a cost-effective option for ACP Composites’ specialized medical positioning table design.

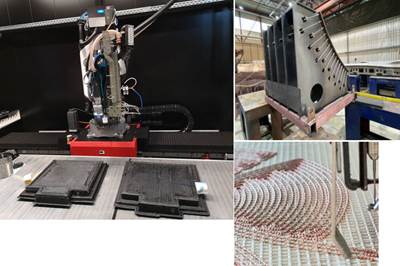

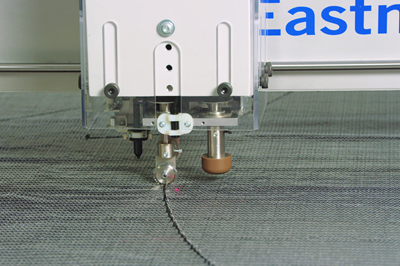

Read MoreAutomated Cutting of Composites Reinforcement Saves Time and Material, Improves Quality

Automated cutting of reinforcement materials is fast, accurate and reliable. It reduces labor costs and material waste and can substantially boost throughput.

WatchUpdate: Lower wing skin, Wing of Tomorrow

Airbus is evaluating several advanced composites technologies as part of its Wing of Tomorrow program. Among these is liquid resin infusion of the lower wing skin, being developed by Spirit AeroSystems.

Watch