Researchers introduce capillary-driven method for continuous fiber 3D printing

The LITA 3D printing system from the University of Delaware shows potential for in situ cure for high-performance carbon fiber composite parts.

Source | University of Delaware

New research in continuous-fiber 3D printing shows potential for additively manufactured composite parts for a range of industries — including space. , researchers from the University of Delaware’s (Newark, Del., U.S.) Center for Composite Materials (CCM) recently introduced a lab-scale method for continuous-fiber 3D printing that incorporates robotics and a capillary-based, in situ heat cure system for fast, additively manufactured carbon fiber composite parts using high-temperature thermoset resins.

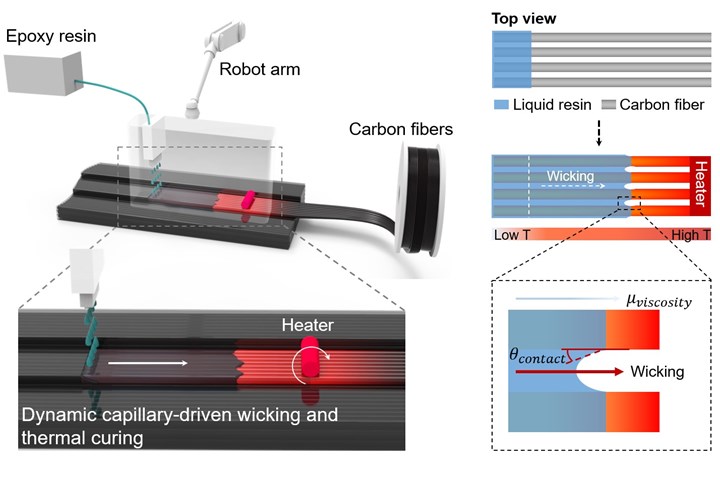

“We call it one-step 3D printing,” says Dr. Kun Fu, assistant professor at the University of Delaware and an author on the study. Called the localized in-plane thermal assisted (LITA) 3D printing method, the system comprises an all-in-one printhead mounted on a robotic arm that includes carbon fiber dispensed from a spool, a guiding bar, a liquid resin nozzle and an electric heater. As the fiber is placed onto the part surface, liquid resin is sprayed onto the fibers and is immediately followed by the heater, which, Fu explains, both aids in infusion and in curing of the part. Fu adds that the heating process reduces the viscosity of the room-temperature resin, helping it to infuse into the fibers without need of a vacuum along capillaries, or tube-shaped gaps, between the fibers. Depending on the needs and size of the part being manufactured, Fu says, the temperature of the heater can be increased or reduced to control the viscosity of the resin.

The current, lab-scale LITA 3D printing system. Source | University of Delaware

This method reportedly enables nearly simultaneous wetting and curing of continuous fibers with thermoset resins, with potential to quickly producing 3D composite components with complex geometries and the high mechanical properties that come from continuous fibers and high-temperature thermosets. The researchers have also demonstrated the system can be used for horizontal and vertical printing, Fu says, and on planar or curved surfaces, adding to the system’s flexibility.

“The technique has been very promising so far,” Fu says, “and as far as we know, we’re the first to publish a technique like this.” According to Fu, the researchers are in the process of obtaining a patent for the technology.

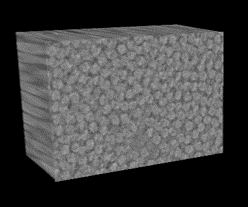

3D CT image of a composite produced with LITA 3D technology. Source | University of Delaware

In addition, the University of Delaware and partner KAI (Dallas, Texas, U.S.) recently received a NASA grant to use the LITA 3D printing method for manufacture of continuous carbon fiber-reinforced composite components for thermal protection systems on NASA spacecraft and lander systems. Fu says that the LITA 3D printing system was chosen for its ability to print with high-temperature resins.

Currently, the technology has only been demonstrated at a small scale – 3K carbon fibers were used for the study – but Fu says the team is working to scale up the robotic system to enable use of wider carbon fiber tows for larger components. The researchers are currently looking for companies interested in collaborating on scale-up and subsequent commercialization of the technology.

To access the Matter article, go to .

Related Content

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More.jpg;width=70;height=70;mode=crop)