Designing the ultimate stand-up fishing kayak

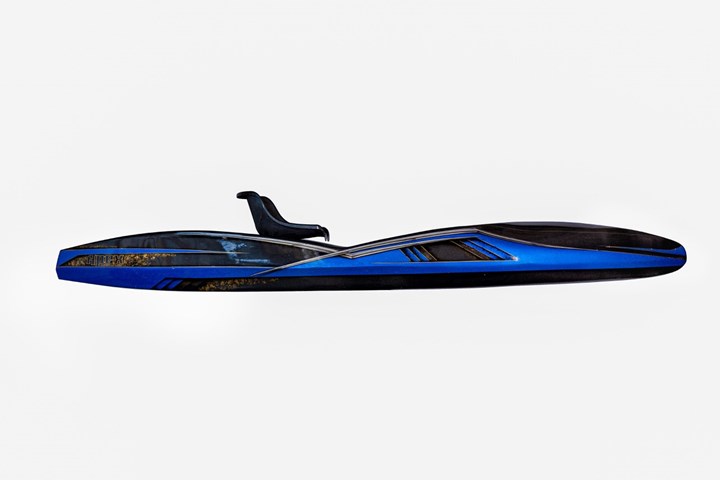

Apex Watercraft’s new Tyr carbon fiber/epoxy prototype reimagines the typical kayak design and promises the highest performance possible.

The carbon fiber/epoxy Tyr fishing kayak promises top-of-the-line performance. Source | Apex Watercraft

Apex Watercraft (Rock Island, Tenn., U.S.) was founded in January 2020 by Eric Jackson, a lifelong kayak competitor and designer. Having competed with high-performance, highly durable carbon fiber kayaks like the 15-pound kayak he raced in the 1992 Olympics, Jackson has set out with his new company to create an all-composite, stand-up fishing kayak that matches the light weight and high performance of racing kayaks with a design that’s simple to use. Despite a few setbacks this spring arising from the start of the coronavirus pandemic, Apex introduced its carbon fiber composite Tyr fishing kayak prototype in June through a Kickstarter campaign.

At its 3,000-square-foot facility on Rock Island outside of Campaign, Tennessee, Apex’s team — a mix of designers, kayak experts and engineers experienced in the composites industry — used CAD software to rethink the design of a stand-up fishing kayak. To achieve the stability needed to stand up while fishing, standard plastic kayaks typically feature a rounded hull designed with holes in the kayak — called scupper holes — to drain off any water that gets into the boat. The Apex team envisioned a planing hull design, meaning the kayak is level with the water on one end to ease entry to the kayak and loading of equipment. A planing hull, Jackson says, is also more stable, reduces draft, enables the kayak to travel faster and is more maneuverable than typical kayak hulls.

The Apex Watercraft team — calling themselves the “Apex Party — consists of Russ Emanis, the lead on composites for both R+D and manufacturing, Bob Blair on Hull design, Colton Breeding on small part design and manufacturing as well as plant management, Craig Heflin on accessories and Mark Nordstrom on the seat design. Source | Apex Watercraft

“Because composite parts can be made super stiff with core materials, we were able to create a full planing hull with no scupper holes in it,” Jackson says. He adds, “Plastic kayaks would be too flimsy to hold their shape if they were designed with the hull shape of my Apex watercraft.”

The 12-foot, 10-inch Tyr kayak also features a unique fin design, tracking system, cork decking, more efficient storage design and magnets within the inside walls of the boat for easy storage of scissors, pliers and other metal fishing tools.

Intrinsic to the overall design is the use of fiber-reinforced polymer instead of plastic — a design choice which drives up the price but that adds the stiffness, light weight and durability Apex Watercraft is aiming for.

“While the chance of breaking a carbon fiber kayak and needing repairing is greater than a plastic boat, the overall longevity is typically much longer,” Jackson says. “It can be repaired easily by the owner and doesn’t ‘wear down’ like a plastic boat. Plastic boats that get much use in shallow water simply lose too much plastic over a big enough area to make repairing it impractical for most people. A high impact epoxy/carbon/Innegra kayak is something you can keep around for a long time.”

The signature Tyr logo is custom airbrushed onto each kayak. Source | Apex Watercraft

Built in March, the first prototype using the new design was cut, hand-laid, and infused with vacuum bagging. The design uses (Port Huron, Mich., U.S.) high-impact infusion epoxy resin and (Kings Mountain, N.C., U.S.) carbon fiber twill fabric, reinforced with H45 PVC foam core and several configurations of Innegra (Greenville, S.C., U.S.) fiber where required. A protective clear coat is applied and then a custom airbrush team adds finishing touches by hand — making sure to make the carbon fiber pattern stand out.

According to Jackson, the company began making its first production boats in August. For more information, email eric@apexwatercraft.com.

Related Content

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRevisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreRead Next

Free-form surfacing optimizes free-style kayak

The 6-ft/1.8m-long Project 54cx kayak, made using aramid and carbon fabric-reinforced composites, weighs only 19 lb/8.6 kg.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More.jpg;width=70;height=70;mode=crop)