Articles

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreThe making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreComposite buildings go monocoque

Superior protection from the elements plus fast, affordable installation and maintenance have quickly made Orenco Composites’ DuraFiber buildings an attractive choice for water and wastewater, communications, transportation and power industry outbuildings.

Read MoreImpressions and takeaways from JEC World 2022

Suffice to say that JEC World 2022, the “Big Show” for the composites industry, exceeded many expectations. Dale Brosius contemplates pervasive themes, conversations and takeaways from the international event.

Read MoreTop 10 Considerations When Buying a CNC Machine for Composites

For a CNC machine to continue to meet or exceed a company’s needs, it must be built and spec’d with these needs in mind.

Read More3D printing and AFP join forces in automotive demonstrator

Bavarian auto industry and TU Munich research how to reduce molding costs by combining continuous fiber and 3D-printed composites.

WatchÂÌñÏ×ÆÞ JEC World 2022 recap: CompPair demonstration

Switzerland-based CompPair illustrates how heat triggers the self-healing properties of its recyclable composite materials, repairing a panel in about one minute.

Read MoreÂÌñÏ×ÆÞ JEC World 2022 recap: GKN Aerospace demonstration

Arnt Offringa, director of the Global Technology Center Netherlands at GKN Aerospace, explains to CW the processes and materials used in a frame assembly for Clean Sky 2’s Multifunctional Fuselage Demonstrator (MFFD).

Read MoreAugmenting engineered thermoplastics with natural fibers

The Paris Climate Accord mandate for net-zero carbon by 2050 has kick-started an innovation revolution for natural fibers and sustainably engineered resins.

Read MoreComposite prepreg tack testing

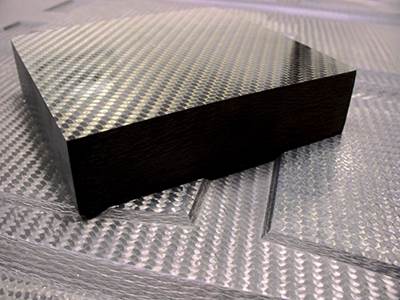

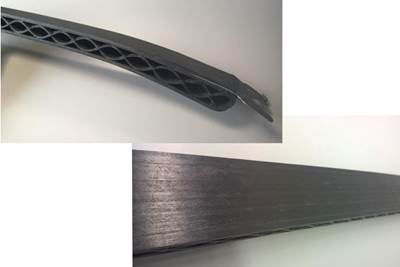

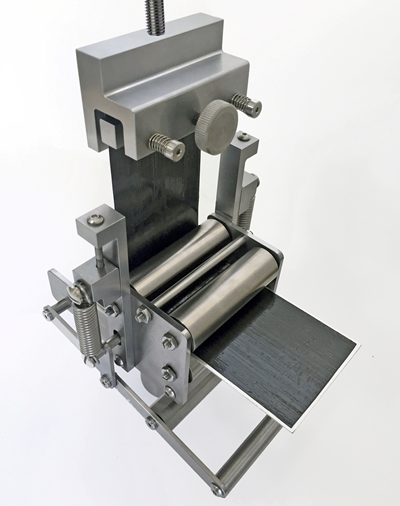

A recently standardized prepreg tack test method has been developed for use in material selection, quality control and adjusting cure process parameters for automated layup processes.

Read MoreData visibility increases efficiency, competitiveness for composite infrastructure solutions company

ClockSpring|NRI builds composite strengthening systems for pipes and civil structures, using Global Shop Solutions ERP software to help track and manage cost and production data.

Read More