Articles

Dustless, mobile solution for on-site wind turbine blade repurposing

Denmark-based Isodan Engineering ApS translated its expertise in mobile, shipping container-based newspaper recycling systems to solve a need for breaking down wind turbine blades on-site for reuse.

Read MoreWe're going to need a lot of propeller blades

As advanced air mobility expands and annual shipsets get into the thousands, the demand for composite propeller blades is expected to skyrocket. What are the implications for the composites supply chain?

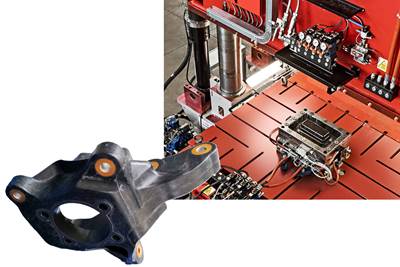

Read MoreA digital twin to validate SMC performance in suspension structures

High-fidelity, anisotropic behavior material card, integrated with process simulation, structural FEA and validated with CT and physical tests enables optimization proven in award-winning SMC suspension knuckle.

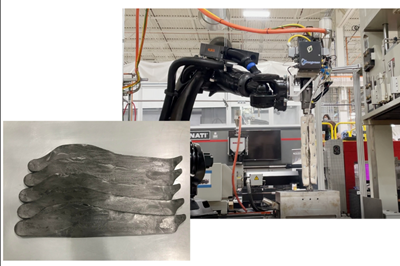

Read MoreLow-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

WatchCFRTP enables better, greener smartphones

Carbon Mobile’s “monocoque” design eliminates separate case, cover and frame, better protects electronics and simplifies disassembly.

WatchTwenco develops sensors for smart molds and process control in resin infusion and composites welding

Non-invasive DEA and NDT Analyzer for multi-parameter monitoring, QA and control, including real time simulation feed and 3D process visualization across and through composite parts.

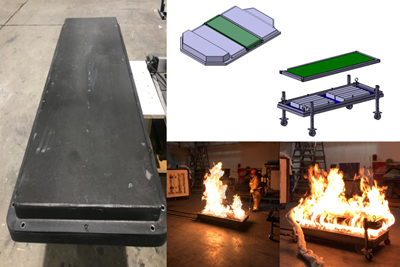

WatchPrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

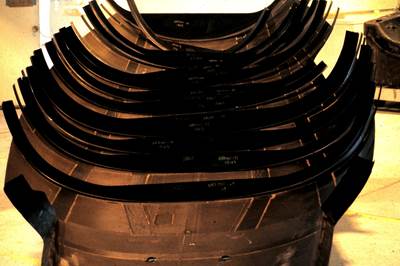

Read MorePlant tour: Dowty Propellers, Gloucester, U.K.

Transforming decades of design and RTM production reliability into more sustainable, next-generation composite propellers.

Read MoreDoing the twist: A look at dimensional issues in high-temperature cured laminates

When it’s not the tooling, the root cause of dimensionally inaccurate composite parts often boils down to two things: fiber form(s) used and laminate symmetry.

Read MoreThe next 10 years in commercial aviation and composites

Aviation Week discusses all-composite plane at Boeing, new composite wing at Airbus and trends driven by sustainability — composites are a key enabler for future aviation.

Read MoreVestas implements composites 3D printing to increase efficiency for blade alignment tools

A Markforged digital repository and multi-material 3D printers enable faster, more accurate and less costly manufacture of a variety of tools and blade components across Vestas sites.

WatchComposites industry continues early 2022 trends into June

As in May, a majority of the components in the Gardner Business Index (GBI): Composites Fabricating continue movement into slowed expansionary growth.

Read More