Articles

Doing the twist: A look at dimensional issues in high-temperature cured laminates

When it’s not the tooling, the root cause of dimensionally inaccurate composite parts often boils down to two things: fiber form(s) used and laminate symmetry.

Read MoreThe next 10 years in commercial aviation and composites

Aviation Week discusses all-composite plane at Boeing, new composite wing at Airbus and trends driven by sustainability — composites are a key enabler for future aviation.

Read MoreVestas implements composites 3D printing to increase efficiency for blade alignment tools

A Markforged digital repository and multi-material 3D printers enable faster, more accurate and less costly manufacture of a variety of tools and blade components across Vestas sites.

WatchComposites industry continues early 2022 trends into June

As in May, a majority of the components in the Gardner Business Index (GBI): Composites Fabricating continue movement into slowed expansionary growth.

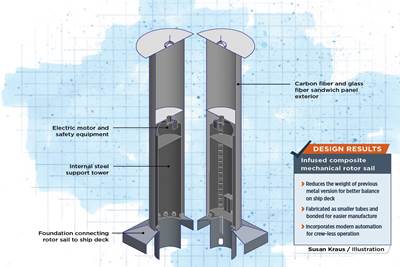

Read MoreModernizing the mechanical rotor sail

Composites are key for Norsepower’s award-winning redesign of a century-old rotor sail for reducing carbon emissions on passenger and cargo ships.

Read MoreWhy aren't composites synonymous with infrastructure?

The U.S. seems poised to invest heavily in infrastructure. Can the composites industry rise to the occasion?

Read MoreCarbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

Read MoreOverair's Butterfly eVTOL prototype to integrate composites-intensive design

Aiming for first flight tests in the latter half of 2023, Overair’s Butterfly aircraft uses Toray carbon fiber/epoxy prepreg strategically to cut weight on its battery-powered, quiet aircraft.

WatchHigh-performance, high-detail continuous 3D-printed carbon fiber parts

Since 2014, Mantis Composites has built its customer and R&D capabilities specifically toward design, printing and postprocessing of highly engineered aerospace and defense parts.

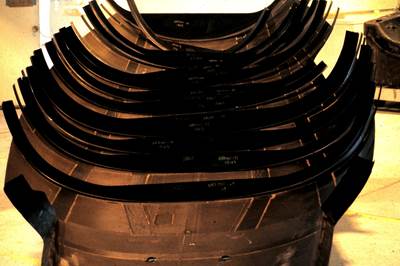

Read MoreMaterials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreSustainability has come to composites and it's here to stay

It might be tempting to think of sustainability as a buzzword, but there are structural changes taking place in the composites industry that signal its permanence.

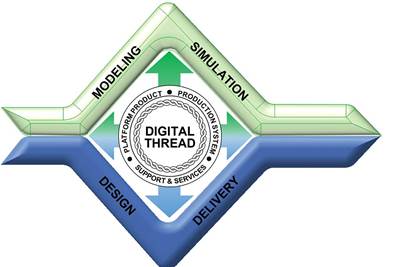

Read MorePlant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

Read More