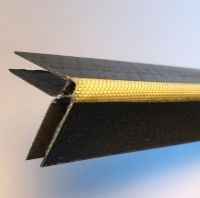

Carbon-Kevlar Hinge

Besting metal hardware in weight, thickness, 3X load capacity and 1 million fatigue cycles with no degradation.

(Brookvale, Australia) develops medium- to high-volume carbon fiber reinforced plastic (CFRP) parts for manufacturers of consumer products, including furniture and sporting goods. “We support many companies in China and Asia, doing prototype development,” explains CEO Geoff Germon. “We also do a bit of work for the aerospace industry.” The Carbon-Kevlar Hinge, however was an in-house project, inspired by parts seen in model aircraft, where CFRP panels were scored and cracked to form a hinge. “This reminded us of the original hinges made from fabric and leather,” recalls Germon. “Our idea was to develop a composite hinge without any metal, that would be super lightweight and also a solution for industries that can’t use metal. It took us two years to optimize the performance of this hinge and develop it to be a manufacturable, packageable product.”

The Carbon-Kevlar Hinge is made from co-molded carbon fiber prepreg wings with a gap between that forms the flex unit. The wings are either a woven carbon fiber/epoxy laminate or a hybrid glass and carbon fiber/epoxy laminate, while the flex unit is woven Kevlar impregnated with a flexible urethane. The wings are available in multiple sizes and the flex unit can be ordered single Kevlar or heavy duty with a double Kevlar layer.

Low thickness, high loading

“Our lightest duty hinge has a closed thickness of 1.6mm, which is probably the thinnest hinge in the world that also has reasonable strength,” says Germon. This hinge is, in fact, very strong, able to sustain a static load of 150 kg in a 50-mm long, 25-mm wide configuration. Germon asserts that a similar metal hinge would probably hold 50 kg. Although this thinnest hinge is designed for bonded assembly, thicker Carbon-Kevlar Hinge products can be bonded, attached with screws or both. “One of the issues with metal hinges is that you can’t bond them, especially stainless steel,” Germon notes. “Our composite hinges, however, are perfectly suited for adhesive bonding.”

|

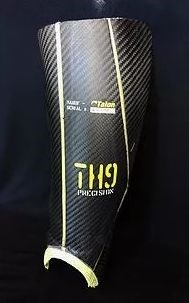

Talon Technologies has developed its Carbon-Kevlar Hinge technology to join multiple hinges with CFRP panels (left); integrate multiple hinges into a complex-curved CFRP part in a single process, demonstrated in adaptable body armor (center); and enable a radiused edge when bent (right). SOURCE: Talon Technologies.

He explains that it is possible to join multiple hinges with CFRP panels. “We can also integrate our hinges into a CFRP part using a single process (see body armor above) and hinges are no longer constrained to flat surfaces because we can mold complex forms into the CFRP wings.” This presents interesting capabilities for applications like shower doors and curved cabinetry while the ability to bond the hinge and eliminate screws is of value in applications susceptible to moisture ingress and corrosion, for example in bathrooms and marine structures. “We can also create a corner hinge with a soft curve — e.g., a radius — vs. a sharp edge, which is a nice design option when making organic forms” says Germon (see below). “We have just produced a hinge with a wooden finish and are also producing a CFRP hinge with integrated fittings for electric cabling,” he adds.

CFRP hardware on the shelf

Germon touts the Carbon-Kevlar Hinge as the first commercial application of carbon fiber that can be a stock item on a retail shelf next to metal products. “Our hinge will soon be added into the ,” he notes, referring to the popular industrial supply source for everything needed to build anything. “The Carbon-Kevlar Hinge price point is the same as a high-quality stainless steel hinge,” he adds. “This is not being sold on the basis of it being carbon fiber, but instead on its superior performance as a consumer item.”

Germon believes that the composites industry has educated the market to think that carbon fiber is always expensive. “In our case, it’s not. We are re-educating the market to understand that it’s a matter of how the carbon composite part is designed and how you use the fiber,” he explains.

Talon Technology has received interest from aircraft interiors suppliers and a prestige auto manufacturer is planning to use the Carbon-Kevlar Hinge in an upcoming model for a seat application. “We are working to develop the necessary impact and shock test data now,” says Germon.

He notes that one Tier 1 supplier of interiors to Boeing has a 700,000-cycle test for hinges. “We just put our hinges through one million cycles of this test, which uses very fast cycling through an 80° arc, roughly 340 cycles/minute, which is more than 5 cycles per second. That would normally kill most metal hinges, but ours showed no change whatsoever.”

Composites education for industrial designers

“We need to reach out and educate industrial designers and engineers about composites,” Germon argues. As an Adjunct Professor in Design at the University of Canberra (Sydney, Australia), he is doing just that, teaching a 3-day course on composites for industrial designers and engineers and working to get a composites module included in the Industrial Design degree. “When we walk around CAMX and JEC, we see plenty of materials scientists, but when have you ever seen an industrial designer?” Germon believes that only when we, as an industry, reach out and educate this group, will we begin to see more consumer products that use composites to deliver value not just marketing.

The Carbon-Kevlar Hinge is one of five finalists for the 2017 CAMX award for Unsurpassed Innovation and will be on display in the awards area at the back of the Exhibit Hall. Go check it out and keep a lookout for Carbon-Kevlar Hinges at a hardware store near you.

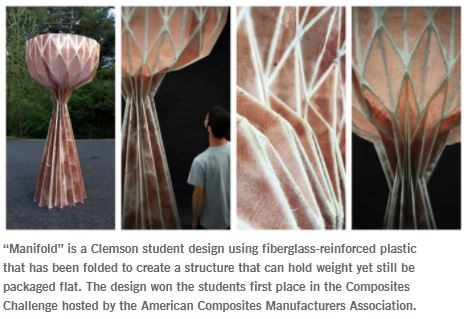

Note that this idea of a composite hinge was independently explored by Clemson University, winner of the ACMA Architectural Division’s 2017 Composites in Architecture Design Challenge with its “MANIFOLD” project. Team leader and Assistant Professor of Architecture at Clemson, Joseph Choma, was interviewed by ÂÌñÏ×ÆÞ Editor Jeff Sloan in Episode 9 of the CW Talks Podcast.

Related Content

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreMFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More