BGF – US link to global composites high-tech

With >50 years in composites, this well-known US supplier is widening its portfolio of composites technologies into opportunities for integrated products and advanced manufacturing.

As a native of North Carolina, I’ve known about BGF Industries (Greensboro, NC, US) for decades. When I started as a technical marketing rep. for DuPont in the early 1990s, BGF was a customer using Kevlar fiber. I knew the company made good quality woven goods for aerospace and that it was acquired at some point by Porcher Industries (Badinières, France).

I’ve always thought of Porcher Industries as a high-quality weaver that also embraced new technologies. For example, its thermoplastic PiPreg products were introduced in 2004. However, after meeting with BGF Aerospace & Defense team in March and then also with CEO André Genton at the 2017 JEC show in Paris, I now see a different story for the Group. That’s what I want to share here.

Porcher Industries was founded just outside Lyon in 1912 as a weaver of silk fabrics. It began producing glass fiber fabrics in 1950. Production expanded internationally with Porcher do Brazil in 1977, followed by acquisition of BGF in 1988 and of Fothergill Crenette in the UK in 1993. Expansion continued with the following:

- Shanghai Porcher Industries was created in 1990

- Porcher Japan KK was acquired in 2008

- Celebrating its 100th year, a new plant in Russia dedicated to high performance carbon fiber textiles for Aerospace and Industrial applications was opened in 2012

- CordTech International in France was acquired in 2016

- P-D Interglas Technologies in Germany was acquired from Preiss Daimler Group in 2017.

New management, new investment

André Genton saw a unique opportunity with Porcher Industries. Genton started his career at Ciba-Geigy and continued at Huntsman Advanced Materials, where he served as president, overseeing a $1.5 billion global business. Genton has amassed over 20 years of experience in composites. Seeking to return to his family home near Lyon, he saw Porcher Industries as a company ready for new opportunities.

Genton became CEO of Porcher Industries in 2016, having secured investment for its acquisition via the London-based private equity fund Warwick Capital Partners, LLP. He then organized the company into 5 market-focused business units:

• Aerospace & Defense

• Industrial

• Automotive

• Building

• Sport & Leisure.

Genton’s goal was to hone the company’s expertise and global R&D, sales and production capacity into a dynamic, unified operation.

BGF is part of Porcher Industries’ global network of R&D, sales and production capacity.

SOURCE: Porcher Industries.

“Our real skill is in fibers, textiles and chemicals processing,” says Genton. ” Other capabilities include material surface and interface and process engineering.

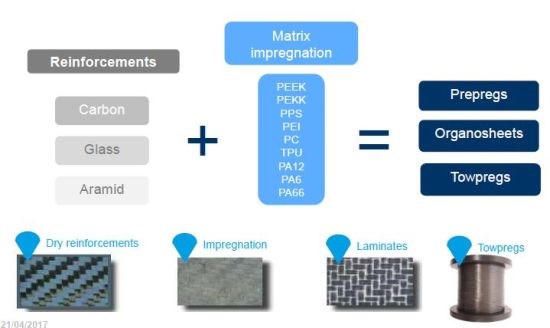

Porcher Industries Pipreg products span a wide array of fiber + matrix combinations, and are available as room-temp stored semipregs, organosheets and also as towpregs for automated fiber placement (AFP). SOURCE: Porcher Industries.

Thermoplastics, AFP and 3D fabric technology

Genton cites thermoplastics as an early example of value-added products developed by the company. Its Pipreg thermoplastic prepreg can be made with a variety of fiber and matrix combinations. Sold as semipreg and towpreg stored at room temperature and also as consolidated laminate sheets (up to 2.5m x 1.5m), Pipreg has been used by DAHER-SOCATA (Tarbes, France) to produce clips for attaching structures to the Airbus A350 composite fuselage and by STELIA Aerospace (Toulouse, France) in its of a full-size thermoplastic composite fuselage with lightning strike protection (LSP) integrated during automated fiber placement (AFP). It has also been used in the pioneering Spheriflex CFRP rotor hub developed with Airbus Helicopters for the H160.

Video of STELIA’s full-size thermoplastic fuselage demonstrator exhibited at the 2017 Paris Air Show.

Airbus Helicopters H160 features the world’s first thermoplastic CFRP rotor hub.

SOURCE: Porcher Industries.

is the company’s industrial market-aimed line of thermoplastic composite fabrics made from commingled glass fiber and polypropylene (PP). Its fabrics offer dry preforms via customized powder binder. The company has also developed , made from cellulose fibers, offering compatibility with bioresins for 100% bio-based composites.

Porcher Industries also offers d3sign fabrics, which offer 3D fabrics, customized bindered dry tows dedicated to Out Of Autoclave, complex design patterns and variable thickness, width and length with fabric density up to 7,000 yarns on multiple layers. This technology has been used to produce aircraft engine parts with improved interlaminar shear to resist impact damage, function integration (e.g., ribs, fittings), complex geometries including variable thickness and cross-section and reduced scrap as well as ease of preforming for resin transfer molding (RTM).

BGF as technology conduit and integration supplier

Hess Goldsmith, the original parent company of BGF, was founded in the late 1800s. Its history with composites began in the early 1940s, working with Owens Corning. By 1956, Hess Goldsmith was weaving glass fiber fabrics in Virginia and opened the world’s first large mill devoted to glass fabrics in 1961. The company was renamed Burlington Glass Fabrics in 1969. Today, it produces a wide range of textile and fiber products, with sales of more than $150 million and 800 employees at six facilities in Virginia, North Carolina and South Carolina.

“We have a long history as a reliable supplier that partners with our customers,” says BGF aerospace & defense sales Steve Flowers. Solutions for composites applications make up half of Porcher Industries global business and more than half of BGF’s, with the latter supplying into aerospace, automotive, sporting goods and construction applications. “If you consider a composite where two or more materials are combined into a structure where each retains its identity, but the whole reaches a new level of performance, then everything we do is a composite,” says Flowers. Genton, too, rejects CW’s traditional limits of fiber-reinforced polymer, ceramic or metal matrix. “Our fiber-reinforced rubber products are just as technical and high-performance,” he notes, “and rubber is a type of polymer.”

In this area of non-traditional composites, Porcher Industries and BGF are forward integrators, providing unique solutions for Tier 1 suppliers in aerospace and automotive. The latest example for BGF is its acquisition of a new facility in Virginia to expand its automotive parts manufacturing capacity. “This business began with efforts to recycle a waste stream from our glass fiber weaving operations,” Flowers explains. “We take the waste, chop it and further process to make thermal insulation products which are now used in automotive and high-temperature applications in other industries.” BGF began by selling the glass mat materials, but was then asked by its customer to die cut the materials, basically taking on steps so that the Tier 1 receives a more integrated product. “Then they asked if we receive all of the steel components and assemble with the glass textiles to produce a complete sub-module,” notes Flowers. This is now high-volume production, supplying 100,000-200,000 parts/yr for some models. “We started by supplying glass fiber products and now we are fully integrated.

BGF is no stranger to developing new technology, holding more than 35 patents and commercializing products such as Aerialite X fabrics featuring commingled Innegra and glass or carbon fibers for high-impact and vibration damping in applications such as surfboards, auto racing and protective sports equipment. It also has many developments in processing and surface treatment.

Example of how Porcher Industries and BGF d3sign products can be used to improve performance and cost in composite aeroengine parts. SOURCE: Porcher Industries and BGF.

BGF has been discussing and demonstrating thermoplastic, bindered fiber and 3D fabric technologies with its customers and new business leads in the US. It worked with Matrix Composites (Rockledge, FL, US) to demonstrate near net-shape preforms using the 3D woven fabrics which were then formed into an aeroengine guide vane using resin transfer molding (RTM). “We believe we can help to reduce steps in the supply chain, increase quality and reduce composites part cost.”

At the other end of the industry, both BGF and Porcher Industries are very active in building and construction. “We already supply to one of North America’s largest home builders, D.R. Horton,” says Genton, “and we see a very big future for composites in this market.”

To learn more, visit BGF in Booth R26 at CAMX 2017 (Dec 12-14, Orlando, FL, US) and stay tuned as we report on future developments.

Related Content

Clean Sky 2 outer wing box demonstrator validates OOA LRI, shimless assembly and SHM

Full-scale wing box project achieves TRL 5 with 2% weight reduction and 4% reduction in recurring production costs through improved manufacturing efficiency and assembly processes.

Read MoreCOMPINNOV TP2 project promotes use of thermoplastics in aerospace

Completed in 2023, COMPINNOV TP2 explored thermoplastic composites, enhancing the understanding between prepregs and production methods to foster the potential for French aerospace innovation.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreAM method enables tool-free, energy-efficient thermoset composites production

University researchers highlight how the combination of a thermally curable resin system with photothermal curing eliminates the post-curing steps involved in discontinuous, continuous fiber parts fabrication.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More