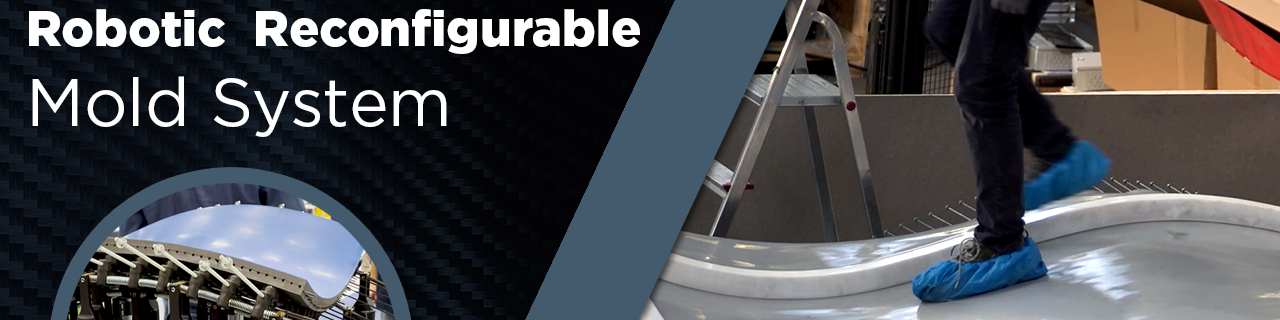

Adapa’s (Aalborg, Denmark) reusable, adaptive mold system replaces the time and waste of CNC machining and one-off mold production by using the composite part’s digital design file to actuate cylinders which form the system’s silicone membrane surface into curved shapes for molding composites, concrete and glass or thermoforming foam, thermoplastic laminates, etc

Related Content

-

TPC, FRP poles and fire-retardant panels

CAMX 2025: Avient Corp. is bringing its latest composites innovations including Polystrand, GridCore and Hammerhead solutions.

-

New brand identity launch aligns with nonwoven portfolio offerings

CAMX 2024: James Cropper, formerly known as Technical Fibre Products, is bringing its new name to the U.S. composites industry, highlighting its specialization in carrier, surface and fire protection veils, among other products.

-

Exacting chemistry streamlines composite surface prep

CAMX 2025: Hawkeye Industries exhibits Duratec, Styrosafe, Styroshield and Aqua-Buff brands for optimal composites coating, compounds and polish solutions options.