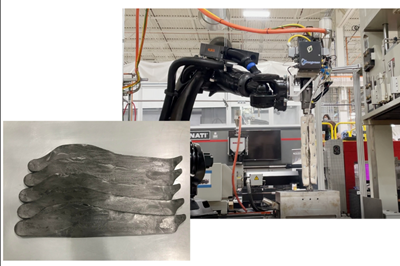

At its nuclear fission technology demonstration facility, one of Kairos Power’s goals is to accelerate nuclear plant construction. In a first project with Oak Ridge National Laboratory (ORNL), Kairos designed and built a 42-foot cast-in-place concrete bioshield column enabled by the use of quickly developed, highly precise 3D printed composite forms (pictured black). Source (All Images) | Kairos Power

(Alameda, Calif., U.S.) began construction on its Hermes Low-Power Demonstration Reactor in Oak Ridge, Tennessee, in July 2024. The site, once completed over the next few years, will serve as a testbed for the company’s ; learnings from this first reactor will also inform construction of a second larger-scale Hermes 2 reactor on the same site.

In May 2025, Kairos Power began construction of nuclear safety-related components for the first Hermes reactor. One challenging aspect of this phase of design has been the development of a complex, 42-foot-tall concrete shielding structure, or “bioshield,” which surrounds the reactor vessel to protect workers from radiation during operation.

Circular or square concrete bioshields are typically constructed around nuclear reactors as monolithic, cast-in-place structures. Kairos Power’s design for the Hermes demonstration reactor aimed to simplify construction by dividing the bioshield into modular sections. The structure comprises four corner pillars supporting four concrete panels that connect with zigzagging joints designed to prevent radiation leakage at the seams.

“I think there are a lot of bold ambitions in nuclear right now, and a ton of opportunity in that space.”

In addition to demonstrating and testing the design, Kairos also wanted to work toward manufacturing processes that would support future scale-up plans. “Historically, Kairos has been very interested in ways to accelerate nuclear construction, but it’s been a challenge in this industry to find the best way to build plants in an efficient and economical way,” explains Edward Blandford, CTO and co-founder of Kairos Power.

Kairos began by investigating the use of precast concrete to cut down on installation time on-site, and spoke with Gate Precast Co. (Jacksonville, Fla., U.S.). One project Gate Precast had successfully completed a few years ago, and that was of interest to Kairos, was a series of geometrically complex precast concrete window facades for a high-rise building in Brooklyn, New York These were fabricated at Gate’s manufacturing site using, instead of traditional wooden molds, mostly 3D printed carbon fiber-reinforced composite molds developed in partnership with the Department of Energy’s (DOE) Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory (ORNL, Tenn., U.S.).

The first demonstration included three columns arranged like a radiation symbol. In practice, four corner columns would be connected via concrete panels to surround a reactor.

The MDF, it turns out, is only a 15-minute drive from the Hermes site, so naturally Gate Precast connected Kairos to ORNL. “We started looking into what Gate had done with ORNL, and it was pretty interesting,” Blandford says. “If we were just making basic cubes, 3D printing would be a very inefficient way of doing it. You’d just get big metal or wood forms and move on. What ORNL has done is develop a process to very quickly produce more advanced geometries that are difficult to fabricate through conventional means; that’s where the real opportunity is.”

Plus, he adds, “We were able to leverage all of the work that Oak Ridge had done developing their large-format 3D printing with carbon fiber composites. A lot of that early work had already been de-risked, and we were simply able to leverage it for our specific application.” [See sidebar below for more on ORNL’s work in large-format additive manufacturing (LFAM).]

The partners ultimately received funding as part of the DOE’s multi-year SM2ART Moonshot Project, led by the MDF with the University of Maine (UMaine, Orono, U.S.), and began working on plans for the shielding demonstration.

Designing the forms: Complex geometry, tight tolerances, high pressure

While precast concrete and pre-assembly remain goals for Kairos’ reactor deployments, for this demonstration, three columns would be cast in place using the 3D printed composite forms.

Based on Kairos’ column designs, ORNL designed and simulated the forms to be printed, with support from Kairos. Each of the three forms comprises three 10 × 10-foot pieces designed to stack and connect together like highly precise Lego blocks.

For this project, the forms were transported from each manufacturer to the Hermes site. In future, Kairos is looking toward off-site preassembly options as well.

“There were two extreme challenges — the geometry and the tolerance,” explains Ahmed Elhattab, senior engineer at Kairos Power. The zigzag shape was developed both to most efficiently prevent radiation leakage and to connect with the rest of the bioshield, and required a tolerance of 1/16 of an inch. “That’s why we needed the 3D printed composites. With wood, you can do the geometry. But to get the tolerance, it’s extremely challenging.”

Another challenge was ensuring the forms were able to withstand the pressure created by pouring the 40-foot concrete column. For this demonstration, the forms were designed to withstand up to 20 psi of pressure. “To give perspective,” Elhattab notes, “regular forms are designed for 1/5 of that value, so we usually can’t exceed a maximum pouring height of 4-foot-high sections of concrete at a time. Then, the concrete needs time to set before you can start pouring again. In this project, we demonstrated we can go all the way up to an 8-foot pouring height.”

Ryan Dehoff, director at the MDF at ORNL, explains that while he and his team were designing the form, the printing process also had to be designed and adjusted accordingly. “With the case of Kairos, geometric accuracy and tolerance are obviously very important. So we collected print data along the way on the initial prints to give some level of understanding on the accuracy of the printing process. We also overlay that print data with the actual geometric data from a light scanner, and we can ensure the quality of the final part.” Modifications were made to the printing process to achieve better adherence between layers during printing, for example.

The MDF at ORNL performed several initial test prints and contributed final demonstrator forms alongside manufacturing partners.

The final three forms were printed using chopped carbon fiber/ABS pellets supplied by Airtech (Huntington Beach, Calif., U.S.). Dehoff notes, “All of this work was done with feedstocks we’ve worked with heavily in the past, so it was pretty low-risk to understanding how these materials are going to behave.”

To speed the printing time, the MDF and partners Additive Engineering Solutions (AES, Akron, Ohio, U.S.) and Haddy (St. Petersburg, Fla., U.S.) each printed and machined the three stackable pieces of a form. These were all transported to the Hermes site for assembly.

Each printing company used the same design and feedstock, but different large-format printers. “There’s not a dramatic difference between them, which overall, I think is a very promising result that came out of this. There are a lot of options in industry to implement these types of technologies,” Dehoff says.

14-day success story and long-term ambitions

The entire project, from initial design to the final 3D printed form, took place over only 14 days. In comparison, if it had been made from wood or steel, it would’ve taken at least 6 weeks, Elhattab says. “It was extremely impressive, especially given that it was three identical products from different companies.”

Plus, unlike a wooden mold that can only be reused a couple of times, “composite molds are very reusable — we can get hundreds of pours into these materials,” Dehoff says. “It really changes the economics, depending on what you’re trying to do.” For example, Kairos could develop a scalable commercial version of its nuclear facility, and lock in a design concept so that the molds could be reused to build standardized structures at multiple sites.

Part of the construction crew stands in front of a column under construction during the concrete pour.

What’s next? This demonstration serves as a precursor to the columns that will be ultimately built and tested as part of the Hermes reactor building. Through the SM2ART project, Kairos and ORNL are continuing to advance and optimize the technology and materials.

“Now that we know this is a feasible method, we can incorporate it into our design approach. The ability to test, prototype and get that input early on is critical. The expediency is helpful,” Blandford says.

“Right now, we are scaling up and envisioning how to apply different materials,” Elhattab adds. This includes lower-cost glass fibers, and even bio-derived feedstocks with ORNL’s partner the UMaine Advanced Structures and Composites Center. The partners are also working on even larger forms using UMaine’s large-format 3D printer.

Dehoff concludes, “I think there are a lot of bold ambitions in nuclear right now, and a ton of opportunity in that space, and so driving towards these unique applications to enable that — and not only that, but reducing costs and reducing time to market — are right in line with where we need to be.”

Related Content

CFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read MoreScaling up thermoplastic composites recycling

Thermoplastic composites are always said to be “recyclable.” Netherlands-based recycler Spiral RTC discusses the process, challenges, applications and opportunities to building a real recycling ecosystem.

Read MoreSpanish startup to ramp up production of “recyclable” EV prototype

Liux’s BIG electric vehicle features multiple structural components manufactured via RTM from flax fabric and a thermoset resin said to enable the entire component to be recycled and reused again.

Read MoreComposite wrap system combats corrosion in industrial tank repair

A fiberglass and carbon fiber composite wrap system enabled an Australian nickel mine to quickly repair a stainless steel ammonium sulphate feed tank and protect against future corrosion.

Read MoreRead Next

Composites speed concrete facade fabrication

The 45-story One South First building, on the 11-acre Domino Park campus in Brooklyn, N.Y., features a geometrically complex concrete facade made, in part, with composite molds fabricated using large-format additive manufacturing.

Read MoreLow-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More

.jpg;width=70;height=70;mode=crop)