Cincinnati Incorporated

7420 Kilby Rd.

Harrison, OH 45030 US

513-367-7100

info@e-ci.com

About Cincinnati Incorporated

Medium and large format additive manufacturing system and other CNC machining systems

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

Cincinnati Incorporated Supplies the Following Products

- Composites Controls & Software

- Laser

- Laser Cutting Systems

- Machinability Databases

- Machine Maintenance & Repair

- Machine Monitoring

- Nesting Software

- Other Manufacturing Software

- Press Brakes & Shears

- Robots

- Training & Workforce Development Services/Software

Editorial, News, and Products

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

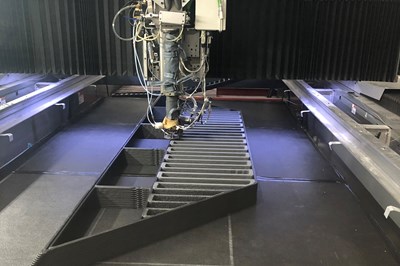

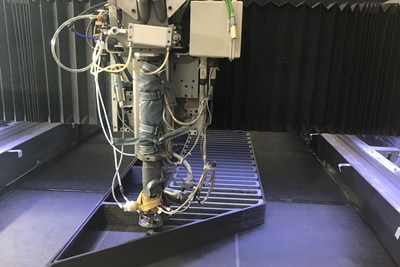

Low-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

-

Additive for Composites and Composites for Additive

ÂÌñÏ×ÆÞ’s Jeff Sloan joins Peter Zelinski in an episode of the AM Radio podcast about how composites and 3D printing are changing one another.

-

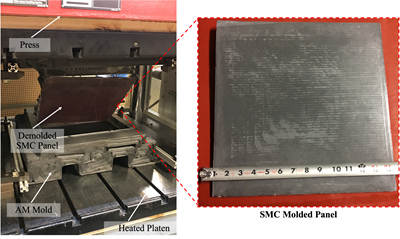

Can 3D printing debottleneck prototype tool production?

Preliminary IACMI/ORNL study evaluates viability of using polymer additive tooling to compression mold SMC.

-

Additive manufacturing adds versatility to large marine structures

Dive Technologies and Moi Composites are among those extending composite 3D printing’s design flexibility past prototyping and into customizable end-use parts.

-

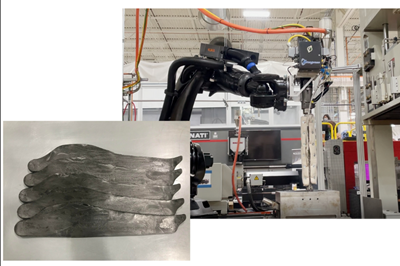

Cincinnati’s BAAM proves utility of recycled materials in AM

Cincinnati Inc. modified the extruder of its Big Area Additive Manufacturing (BAAM) system to be able to process virgin carbon fiber/ABS and recycled carbon fiber/ABS.

-

Cincinnati Inc. BAAM printer demonstrates 3D printing with recycled composites

Dual-material thermoplastic extrusion system produces monolithic composites tool exceeding 10 feet in length, without manual intervention.

-

Ohio State CDME advances AM technology with Cincinnati Inc. MAAM printer

With an additive machine that prints ULTEM, PEEK and PEKK thermoplastics, university researchers and students expect to take 3D printing to new heights, including printing a fully functional turbine and internal combustion engines.

-

People in Composites: December 2020

CW’s December people roundup include new appointees for Cincinnati Inc., Polygon Composites, Exel Composites, Vectorply, Northrop Grumman and more.

-

ORNL develops 3D-printed composite machine base

In a recently reported project from Oak Ridge National Laboratory, carbon fiber and large-format 3D printing were used to help create a solution for machine tool outsourcing.

-

Cincinnati Inc., Multiax America partner for 3D printing turnkey

The turnkey solution is said to enable both companies to expand their customer bases, and provide needed additive production systems solutions.

-

Composites speed concrete facade fabrication

The 45-story One South First building, on the 11-acre Domino Park campus in Brooklyn, N.Y., features a geometrically complex concrete facade made, in part, with composite molds fabricated using large-format additive manufacturing.

-

Cincinnati Inc. to offer BASF 3D printing materials for SAAM HT

BASF’s ABS plastic, carbon PET and recycled PET are now offered for use with Cincinnati Inc.’s Small Area Additive Manufacturing Machine.

-

Cincinnati Incorporated and Marine Concepts to debut 3D printed molding tool

Cincinnati Incorporated’s Big Area Additive Manufacturing (BAAM) machine was used to create a 3D printed light resin transfer molding (LRTM) tool that will be showcased at the IBEX boat-building trade show in Tampa Florida October 1-3, 2019.

-

Big additive machines tackle large molds

In commercial aerocomposites fabrication, molds reign supreme, but they are expensive. Large-format additive manufacturing systems are poised to make production-ready molds quickly and affordably.

-

Cincinnati Inc.'s 3D printed trim tool for the 777X wing tip

Cincinnati Inc. explains the process for creating and their record-holding additively manufactured tool.

-

CAMX 2018: Big changes coming

3D printing goes thermoset, pultrusion aims at automotive, a polyester resin with Tg>250°C and much more from the Dallas exhibit floor.

-

Cincinnati Inc. launches new carbon fiber-reinforced resin for additive manufacturing

New material for Cincinnati Inc.’s Small Area Additive Manufacturing system (SAAM) is designed for custom tooling and fixture applications

-

Musings on my first CAMX

Insights and inspiration from the 2018 Composites and Advanced Materials Expo which was held in Dallas, TX, US last week.

-

Sustainable, inline recycling of carbon fiber

Shocker Composites and R&M International are developing a supply chain for recycled CF with zero knockdown vs. virgin fiber, lower cost and, eventually, lengths delivering structural properties close to continuous fiber.

-

Plant tour: Spirit AeroSystems, Wichita, KS

Spirit AeroSystems was an established aerospace supplier when it earned that distinction, winning the contract for the Boeing 787’s Section 41. Now its sights are set on the next generation of aircraft.

-

Additive manufacturing: Big and going commercial

A demonstration of large-format 3D printing delivers parts for an excavator cab, from CAD data to ready for assembly, in only five hours.

-

CAMX 2017: Highlights from the floor

3D printing and nanotechnology developments promise to cut time and cost in composite structures production while recycling and sustainability continue to grow in importance.