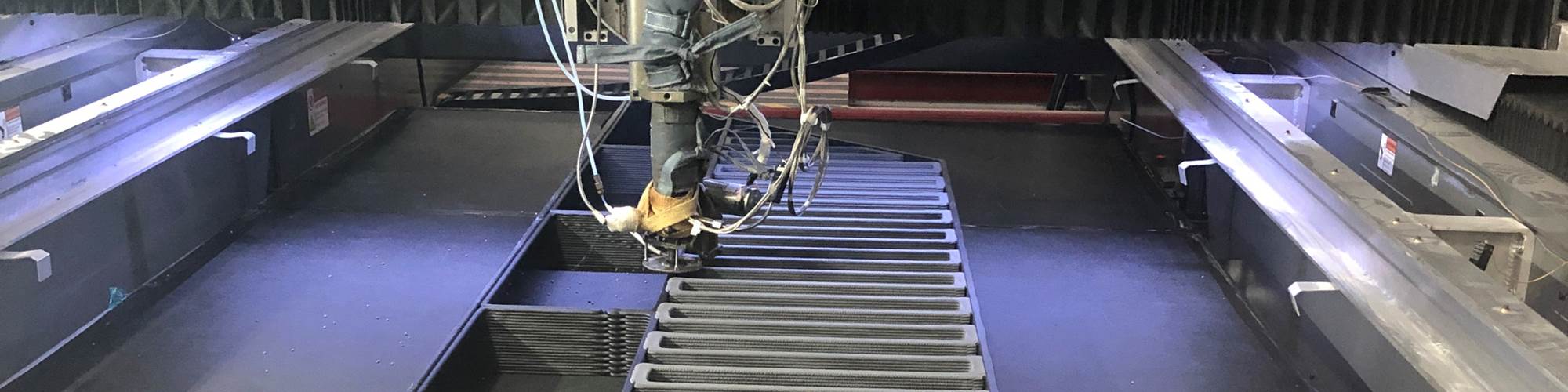

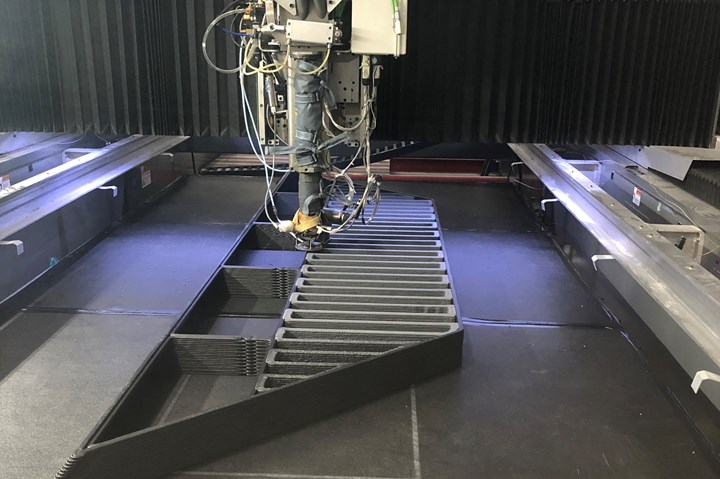

Cincinnati Inc. BAAM system printing with recycled materials. Photo Credit: Cincinnati Inc.

Cincinnati Inc. (CI, Harrison, Ohio, U.S.), manufacturer of the Big Area Additive Manufacturing (BAAM) machine, the world’s first large-format additive manufacturing system, has been used to demonstrate that recycled materials can be used for 3D printing by producing one of the largest monolithic multi-material objects to date. The demonstration successfully proved that large-scale, multi-material printing can be done effectively and economically with recycled composite materials.

The large-format, multi-material print was achieved by making modifications to the BAAM, including a new extruder design that accommodates a dual-feed system. “The objective of this particular study was to demonstrate printing of a multi-material composites tool including transitions, exceeding 10 feet in length, containing recycled material and printed without manual intervention,” says Alex Riestenberg, CI’s additive manufacturing product manager. The part selected for the demonstration was a single facet of a precast concrete tool used in the production of commercial window panels for a high-rise development in New York City. The mold weighed approximately 400 pounds, with a length of 10 feet, 10 inches. Print time was approximately seven hours.

The two materials used in the build were a blend that contained 100% recycled carbon fiber/ABS and virgin carbon fiber/ABS and ABS syntactic foam. The enabling technology, developed with Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn., U.S.), was a large dual-material thermoplastic extrusion system that allows the user to print with multiple materials in a single build using one extruder.

“The source of material fed into the extruder is switched on the fly at specific times during a print by sliding two material ports back and forth over the infeed to the extruder,” says Riestenberg. “The system also includes a material blender outside the frame of the machine that can blend specific amounts of different materials and fillers on the fly for specific custom material grades.”

Related Content

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.