Low-temp demold BMI prepreg enables low-cost master molds

CAMX 2025: Kaneka Aerospace 250°F BMI prepreg tooling, developed in collaboration with Janicki Industries, elevates composite tooling capabilities.

Share

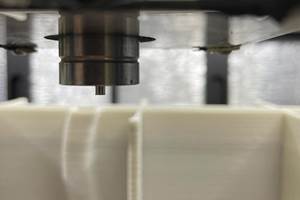

First 250°F BMI ply after debulk to fiber-reinforced polymer (FRP) master. Source| Kaneka Aerospace

Kaneka Aerospace (Bernicia, Calif., U.S.) is co-presenting with Janicki Industries (Sedro-Woolley, Wash., U.S.) composite tools that have been developed using a novel bismaleimide (BMI) prepreg that achieves reduced cost and lead time without sacrificing performance.

The company’s novel BMI prepreg imparts several notable features:

- Optimal thermal oxidative stability makes it resistant to microcracks and weight loss is less than half of legacy BMI tooling prepregs

- Demoldable after initial cure at 121°C (250°F)

- Uses technology that enables thermal stresses to be relieved during thermal cycling while maintaining shape.

After successful fabrication and evaluation of the flat tooling plates, new tools using the BMI prepreg were fabricated. These tools included stringer-like geometry to evaluate the effects of ¼" and ½" concave and convex radii on laminate quality. Elevated temperature debulks were used periodically to remove bulk and inspect laminate quality over radii. The tools were consolidated and cured in an autoclave and then freestanding post-cured in an oven using cycles provided by Kaneka. Samples were taken after each cure for microscopy.

The tools were machined using the same parameters and end mills as used for 350°F cure BMI tooling prepreg, followed by sanding to remove mill scallops and achieve surface roughness typical for aerospace composite tooling.

The BMI tools are capable of being cured initially at 121°C (250°F) followed by a 204°C (400°F) cure in a freestanding manner. Simulated life cycle testing of 250°F BMI shows similar durability when compared with industry standard 350°F cured BMI tooling prepregs. The ability to cure BMI at 250°F, Kaneka reports, allows for significantly more material options to rapidly produce economical patterns or “direct masters.”

Kaneka Aerospace specializes in high-performance composite materials for the aerospace and industrial markets. Its prepregs, resins and adhesives provide distinguishing properties that enable customers to achieve value beyond lightweight and strength.

Related Content

-

Optimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

-

Norco GFRP molds meet high-quality cast concrete beam production needs

A project with P&M successfully achieved manufacture of six 20-meter-long architectural beams for an R&D facility with near-seamless surfaces and on a tight production schedule.

-

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Related Content

Optimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MoreNorco GFRP molds meet high-quality cast concrete beam production needs

A project with P&M successfully achieved manufacture of six 20-meter-long architectural beams for an R&D facility with near-seamless surfaces and on a tight production schedule.

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MoreJamco America partners with Airtech for 3DP tool recycling

Aerospace manufacturer joins forces with composite materials company to achieve sustainable manufacturing practices that overcome traditional composite layup tooling.

Read MoreRead Next

Ultrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More