Low-consumption, modular VMC pushes precision and performance

CAMX 2025: Breton highlights how the Hawx E2 five axis can elevate trimming, milling and drilling operations.

Share

Source | Breton

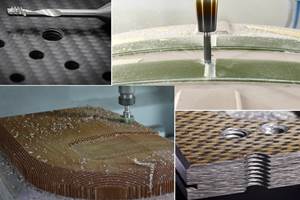

The Breton SpA (Castello Di Godego, Italy and Sarasota, Fla., U.S.) Hawk E2 is a five-axis vertical machining center (VMC) that pushes the limits of performance and precision in composites manufacturing. Engineered to meet the toughest demands of aerospace, automotive and advanced material applications, the Hawk E2 is capable of trimming, milling and drilling complex 3D shapes made from light alloys, polymers, resins and composite materials.

At the heart of the Hawx E2 is a modular gantry design that enables a customizable configuration, easily adaptable to evolving manufacturing needs, featuring a rigid structure, high-speed capabilities and advanced Sinumerik One control system. Orthogonal Head-Link technology ensures simple and quick installation or replacement of additional sensors, reducing service time and overall maintenance costs.

The Hawx E2 is safety-focused. A dual safety system includes an emergency brake on the Z-axis to prevent unintentional axis descent. This design also enables safe operations with open guards, such as tool verification and workpiece inspection while the spindle is running at low rpm. Additionally, an Eco collision avoidance system prevents accidental collisions between components.

What sets the Breton Hawx E2 apart? According to the company, the modular system’s scalable architecture ensures it fits within a company’s workspace, considering future growth. Its multi-material versatility addresses advanced composites. And its high-precision, heavy-duty design makes it useful in demanding industries

Related Content

-

CFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

-

Addressing rivet hole drilling challenges for aerospace composites

Kennametal explores technological advancements in composite drilling, including stacked laminates, to meet aerospace applications and sustainability challenges.

-

Apache Aerospace highlights MX-5 self-feed countersink tool

Third-generation design approved by U.S. aerospace manufacturers targets simplified operations for metal and composite materials cutting.

Related Content

CFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read MoreAddressing rivet hole drilling challenges for aerospace composites

Kennametal explores technological advancements in composite drilling, including stacked laminates, to meet aerospace applications and sustainability challenges.

Read MoreApache Aerospace highlights MX-5 self-feed countersink tool

Third-generation design approved by U.S. aerospace manufacturers targets simplified operations for metal and composite materials cutting.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More